How should prepreg be stored?

Prepregs are typically stored refrigerated; for example, HexPly prepregs from Hexcel Corporation in the US are typically stored in a -18°C cold storage facility.

To prevent moisture absorption, the prepreg should be allowed to warm to room temperature before opening the polyethylene bag (warming to room temperature for an intact package may take up to 48 hours).

Generally, at -18°C, the shelf life of prepregs is 12 months from the production date. The shelf life at -18°C and at room temperature is usually printed on the label of the prepreg product packaging.

The tack life and external life of prepregs at room temperature (23°C) will vary depending on the type of resin.

Hygiene and safety measures when using prepreg

The prepreg is covered with a protective film before laying; the film is removed after cutting, therefore, direct contact with the prepreg is practically nonexistent.

Unlike wet processes (dry fibers, liquid resin), the prepreg process produces very little fiber dust and eliminates splashing, leakage, and spillage.

Prepreg does not volatilize at room temperature.

At room temperature, the prepreg's viscosity is at a low to medium level.

However, all prepregs should still be handled with caution, such as always wearing gloves that cover the arms to avoid skin contact with the product.

Repeated touching of prepregs without protection can cause allergic reactions.

Processing cured products will generate dust containing fibrous materials, which should be avoided from inhalation. It is recommended to install a dust collection device in the cutting area.

To prevent fire and explosion, dust formation should be avoided during the processing of cured products, and sources of ignition should be kept away. Dust containing carbon fibers is conductive.

Aramid fiber, also known as poly(p-phenylene terephthalamide), possesses excellent properties such as ultra-high strength,

high modulus, high temperature resistance, acid and alkali resistance, and light weight.

It was successfully developed and commercialized by DuPont in the 1960s (trade name Kevlar).

Therefore, before the advent of carbon fiber, aramid fiber dominated the high-performance fiber market.

Characteristics of aramid fiber composite materials

2.1 High impact resistance and crack resistance

Aramid fibers possess excellent impact resistance and, due to their toughness and ability to absorb large amounts of energy, will not break under pressure.

They are widely used in the manufacture of bulletproof vests, armor for boats, kayaks, and military vehicle components.

The impact resistance of aramid fiber composites is five times that of carbon fiber composites (tested using the drop hammer impact method).

This extraordinary resistance to impact or bullets is caused by the long atomic chains that form the aramid structure.

Given their superior impact resistance, aramid fibers are widely used in military applications, such as in the manufacture of bulletproof vests and tank armor materials.

Bulletproof vests are typically made of dozens of layers of aramid (such as Kevlar) with a ceramic plate between the layers.

The protective shields used on some armored vehicles (such as the US M1 tank) are made of steel-aramid-steel materials and can withstand anti-tank missiles with a diameter of up to 700mm.

In addition to protecting the tank itself, the steel-aramid-steel shield also protects the crew by absorbing the kinetic energy generated by penetrating missiles.

Another application of Kevlar is on the Boeing AH-64, a US military main attack helicopter equipped with Kevlar rotors.

Here, Kevlar can stop bullets with a maximum diameter of 23 mm.

Due to its high impact resistance, Kevlar is widely used in the construction of boats and kayaks, such as the hulls designed for the Volvo Ocean Race, one of the most challenging sports.

Most high-performance kayaks for water sports are made of aramid fibers or carbon fiber/aramid fiber blends.

2.2 Low density/low weight

Aramid fibers possess extremely low weight, an advantage in the manufacture of composite materials.

While carbon fiber composites are considered very light,aramid fiber composites are approximately 20% lighter.

Using aramid fabrics in composites increases impact and abrasion resistance and reduces the weight of composite components.

The density of aramid fibers is approximately 1.45 g/cm³, while the density of aramid-epoxy composites is approximately 1.3 g/cm³.

This calculation is based on a mixed density of epoxy resin and curing agent of approximately 1.1 g/cm³,

and the advanced technology used in the composite production process, namely autoclave prepreg.

In contrast, carbon fiber composites, Generally considered very light, have a density close to 1.55 g/cm³.

Overall, aramid fiber composites are 20% lighter than carbon fiber composites.

How to compare the weight of aramid fiber composites with metals? Aluminum is 2.7 g/cm³, titanium is 4.5 g/cm³, and steel is 7.9 g/cm³.

Therefore, aramid fiber composites are twice as light as aluminum, three or four times lighter than titanium, and six times lighter than steel.

2.3 Moderate stiffness, between that of glass fiber and carbon fiber.

Aramid fiber composites exhibit higher stiffness than glass fiber composites, but significantly lower stiffness than carbon fiber composites.

Similar to carbon fiber, aramid fibers come in many types, including standard, medium, and high modulus fibers, offering varying degrees of stiffness and strength.

The stiffness of different fiber types is as follows:

Glass fiber fabrics – from 72 GPa (standard E-glass) to 87 GPa (S-reinforced glass fabrics);

Carbon fiber fabrics – from 230 GPa (Toray T300) to 588 GPa (Toray HM grade M60J);

Aramid fiber fabrics – from 96 GPa (standard aramid, i.e., Kevlar 129) to 186 GPa (aramid used in the aircraft/aviation industry, i.e., Kevlar 149).

In summary, aramid composites made from standard fabrics have 30-40% higher stiffness than glass fiber composites, but 50% lower stiffness compared to carbon fiber composites.

2.4 Abrasion Resistance

Aramid fiber composites are widely used in easily worn components, such as skid plates protecting racing car engines.

Aramid is commonly used in extraction industries (such as mining) to reinforce conveyor belt rubber belts,

ensuring higher strength and abrasion resistance; according to Kevlar manufacturers,reinforcement can improve abrasion resistance by 50-70%.

Due to these properties, the material can be used in composite materials and workwear, such as cut-resistant safety gloves using aramid fabrics, such as those from Twaron or Kevlar.

2.5 Low Dielectric Constant

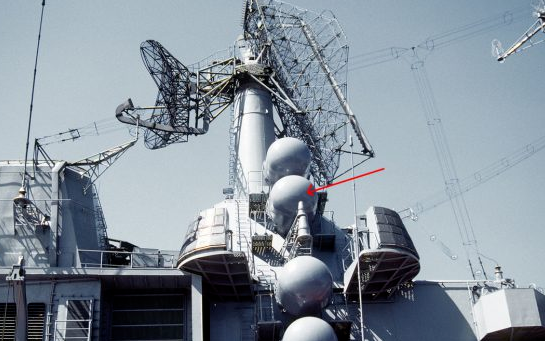

The dielectric constant of aramid fiber composites is as low as ~3.85 (10 GHz), ensuring good signal penetration performance and strength through the aramid radome/antenna.

This type of antenna is widely used for military purposes, such as on military aircraft.

Aramid fiber composite shells/radomes protect antennas from damage and ensure good signal performance.

In contrast, E-glass fiber composites offer a capacitance of 6.1 (10 GHz), resulting in a 60% reduction in antenna signal power and performance.

In addition to aramid, quartz fiber is also used, with a dielectric constant of 3.78 (10 GHz).

2.6 Other Properties

Aramid fibers have low thermal expansion characteristics, are very stable at high temperatures (almost zero), and have a slightly negative coefficient of thermal expansion, equivalent to (-2.4 x 10⁻⁶ /°C). Aramid fibers are excellent insulators and are non-conductive.A particular property of aramid fiber composites is related to vibration absorption, making them suitable for manufacturing vibration-exposed components, such as aircraft structural parts.

2.7 Blending Composites with Other Fabrics

Aramid fiber fabrics can be parameter-tuned for use in carbon fiber and glass fiber composites, providing suppliers of composite products with a variety of possibilities.For carbon fiber composites, impact resistance can be improved by adding several layers of aramid fiber fabric. Hybrid composites composed of 50% carbon fiber

and 50% aramid fiber can improve impact resistance by up to 25% compared to composites made of carbon fiber alone.

1.How does 3D printing in the aerospace industry use carbon fiber to manufacture different parts?

Currently, the application of carbon fiber 3D printing in the aerospace field is limited.

Extensive qualification is required before new materials and processes can be used in aerospace.

However, many aerospace companies are using 3D-printed carbon fiber parts as supports and specialized tools.

3D printing is used to manufacture parts in limited production runs, where otherwise, lead times would be very long.

Many repair and maintenance tasks require specialized tools, which are costly and have long lead times.

With 3D-printed carbon fiber, both lead times and costs are now being significantly reduced.

2.What are the advantages of carbon fiber compared to other 3D printing materials?

Compared to other 3D printing materials, carbon fiber printed parts have the advantage of higher strength.

Most 3D printed parts are made of relatively weak materials like PLA or ABS, meaning these parts cannot be used for structural purposes.

However, 3D printed carbon fiber materials have strength comparable to aluminum. This opens up many application areas for 3D printed parts.

3.Is carbon fiber stronger than steel?

Yes, when comparing their respective strength-to-weight ratios, carbon fiber is stronger than steel.

Although both steel and carbon fiber have an elastic modulus of 200 GPa, steel is five times heavier than carbon fiber.

This high strength-to-weight ratio is why carbon fiber is likely to be favored in many applications.

4.Is carbon fiber stronger than aluminum?

Yes, carbon fiber is much stronger than aluminum. Aluminum has a tensile strength of up to 570 MPa, while ultra-high modulus carbon fiber has a tensile strength exceeding 5.5 GPa.

5.What is the difference between carbon fiber and carbon fiber 3D filament?

Both traditional carbon fiber and 3D-printed carbon fiber offer increased strength and reduced weight, but their applications differ significantly.

Traditionally, carbon fiber is a woven fabric coated with resin and then cured. Traditional carbon fiber is typically made into large panels and tubular sections,

but it can also be used to create scaffolds. 3D-printed carbon fiber is either diced into microfilaments and added to filaments before being printed into parts that often have complex geometries,

or it is printed as a single continuous filament within discrete layers of a 3D-printed part.

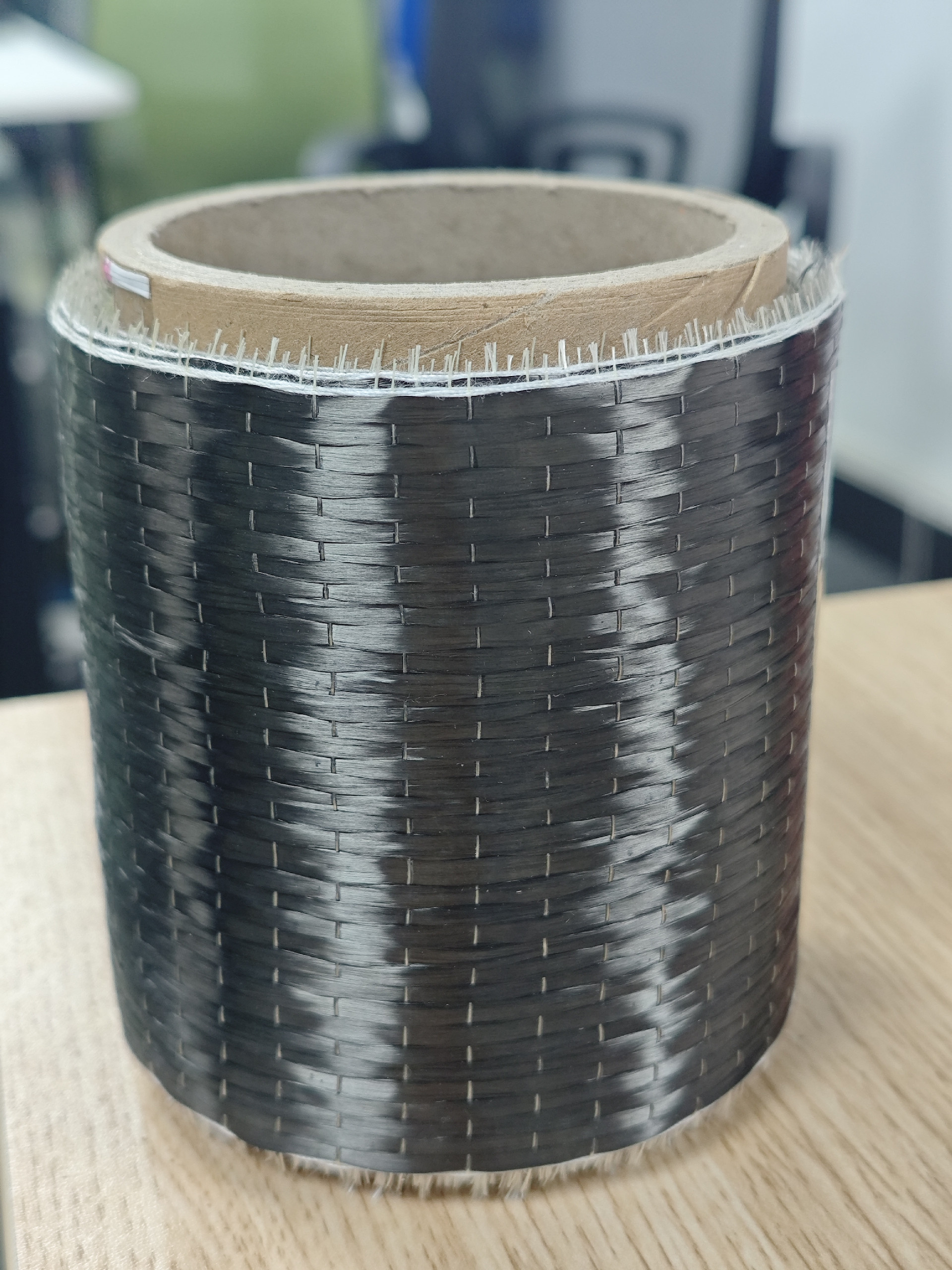

Unidirectional carbon fiber cloth

Unidirectional carbon fiber cloth has a large number of carbon fiber bundles arranged in one direction (usually the warp), while only a small number of fine fibers or special hot melt adhesive threads are used for fixing in the other direction. This structure makes its strength mainly concentrated in the direction in which the carbon fiber bundles are arranged.

Advantage

1. Ultra-high directional strength: Unidirectional carbon fiber fabric possesses extremely high tensile strength in its fiber alignment direction, typically several times that of ordinary steel.

Taking unidirectional fabric woven from common 12K carbon fiber filaments as an example, it can easily withstand enormous tensile forces in its dominant direction, making it suitable for scenarios requiring extremely high strength in specific directions, such as the reinforcement of tension zones in beams and slabs in building structures.

2. Excellent impregnation: Due to its relatively simple structure, unidirectional carbon fiber fabric exhibits excellent wetting properties with its matching carbon fiber adhesive.

During construction, the adhesive can quickly and evenly penetrate into the fiber gaps, allowing the carbon fiber fabric to bond tightly to the reinforced substrate, forming a robust composite that effectively transfers stress.

3. Relatively low cost: Compared to bidirectional carbon fiber fabric, unidirectional carbon fiber fabric has a simpler production process and uses less raw material, resulting in a lower overall cost. This gives it a cost advantage in large-scale conventional reinforcement projects, making it highly cost-effective.

4. Convenient Construction: Unidirectional carbon fiber cloth is soft and can be cut to any size according to actual needs. During construction, it can be simply pasted along the tensile direction or perpendicular to the crack direction.

No complicated operating skills or large construction equipment are required, which greatly shortens the construction cycle and makes it easy to ensure the construction quality. Even if the surface of the object to be reinforced is uneven, a high effective adhesion rate can be guaranteed.

If air bubbles appear on the pasted surface, they can be easily solved by injecting adhesive with a syringe.

Disadvantage

1. Weak performance in non-dominant directions: Unidirectional carbon fiber cloth exhibits lower strength in the direction perpendicular to the carbon fiber filament arrangement, resulting in poor resistance to tensile and shear forces.

If the structure is subjected to complex forces in multiple directions, using only unidirectional carbon fiber cloth may not fully meet the reinforcement requirements, presenting certain limitations.

2. Increased risk of breakage: When the direction of the external force is inconsistent with the direction of the carbon fiber filament arrangement, unidirectional carbon fiber cloth is more prone to breakage or damage.

For example, in structural parts subjected to irregular forces, using unidirectional cloth for reinforcement may lead to carbon fiber cloth failure if subjected to forces from unexpected directions, affecting the reinforcement effect.

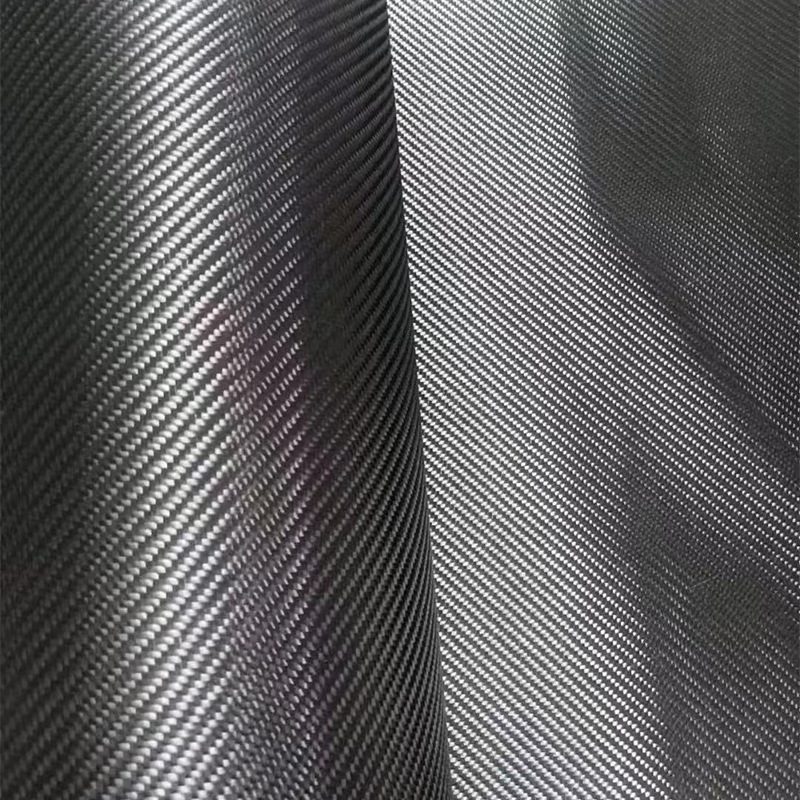

Bidirectional carbon fiber cloth

Biaxially oriented carbon fiber fabric contains a large amount of untwisted roving in both the transverse and longitudinal directions, and is woven in both warp and weft directions. Its texture is diverse, with common patterns including plain weave, twill weave, and satin weave. This structure gives it relatively balanced mechanical properties in both directions.

Advantages

1. Excellent bidirectional load-bearing capacity: It can withstand tensile and compressive forces from different directions, avoiding the disadvantage of unidirectional carbon fiber cloth being subjected to force in only one direction.

In structures with complex stress directions and where the main stress direction is difficult to determine, bidirectional carbon fiber cloth can provide a more comprehensive and uniform reinforcement effect, significantly improving the overall stability and load-bearing capacity of the structure.

2. Adaptability to complex shapes: Due to the characteristics of bidirectional weaving, bidirectional carbon fiber cloth has good flexibility and can better conform to irregularly shaped structural surfaces, such as pipes and irregularly shaped building components.

When reinforcing these special structures, bidirectional carbon fiber cloth can tightly wrap them, fully exerting its reinforcement effect and ensuring that all parts of the structure are effectively strengthened.

3. Wide range of applications: With its excellent bidirectional load-bearing capacity and ability to conform to complex shapes, bidirectional carbon fiber cloth is not only suitable for reinforcing building structures, but also widely used in industrial equipment, aerospace, and other fields.

For example, in manufacturing industrial parts that need to withstand multidirectional stress and some structural components of aerospace vehicles, bidirectional carbon fiber cloth can meet the requirements for high-performance materials.

Disadvantages:

1. Relatively Lower Strength: Although biaxial carbon fiber fabric exhibits good performance in both directions, its strength in each direction is slightly lower than that of uniaxial carbon fiber fabric in its dominant direction.

This is because the interweaving and overlapping of each carbon fiber filament during weaving disperses the fiber strength to some extent, preventing it from achieving the ultra-high strength of uniaxial carbon fiber fabric in any single direction.

2. Complex Weaving Process and High Cost: The weaving process for biaxial carbon fiber fabric is more complex, requiring precise control of the interweaving of carbon fiber bundles in both warp and weft directions.

This places higher demands on production equipment and processes. This results in relatively lower production efficiency and greater raw material waste, leading to a significantly higher price for biaxial carbon fiber fabric compared to uniaxial carbon fiber fabric. In cost-sensitive projects, this may limit its large-scale application.

3. Difficult Impregnation: Due to the relatively thick thickness and complex internal fiber interweaving of biaxial carbon fiber fabric, the impregnation process with the matching carbon fiber adhesive is more challenging.

The glue cannot penetrate into the gaps between each fiber quickly and evenly, which may affect the bonding effect between the carbon fiber cloth and the substrate, and thus affect the reinforcement quality. This places higher demands on the construction process and the technical level of the operators.

How to Choose?

The choice between unidirectional and bidirectional carbon fiber fabric depends on the specific application scenario and structural stress characteristics. If the structural stress direction is clear, with significant tensile force mainly occurring in one direction,

such as the reinforcement of common building beams and slabs for bending resistance, then unidirectional carbon fiber fabric is the preferred choice due to its extremely high directional strength and good cost-effectiveness. However, if the structural stress is complex, with stress in multiple directions, or if the shape is irregular,

such as the reinforcement of irregularly shaped components in some ancient buildings or pipe repairs, then bidirectional carbon fiber fabric can better leverage its advantages in bidirectional stress distribution and its ability to conform to complex shapes.

In the field of structural reinforcement, the application of carbon fiber materials has gradually become a common choice. As two important carbon fiber reinforcement materials, carbon fiber cloth and carbon fiber board play a key role in reinforcement and repair projects.

However, there are significant differences between them in terms of performance, construction methods and applicable scenarios.

1.Differences in performance characteristics

Carbon fiber cloth is typically a thin sheet of woven fibers. Its primary characteristics are its lightness, thinness, and flexibility.It possesses excellent tensile strength and corrosion resistance, effectively increasing the load-bearing capacity of the reinforced structure. Its flexibility allows it to conform to a variety of surfaces, making it suitable for reinforcing irregularly shaped or curved structures.

In contrast, carbon fiber panels are made from multiple layers of carbon fiber cloth through pre-impregnation, pressurization, and curing processes. Carbon fiber panels stand out in reinforcement for their high stiffness and strength, effectively controlling structural deformation and improving overall stiffness. Due to their relatively rigid nature, carbon fiber panels are more suitable for structures that require rigid support, such as beams and columns.

2.Differences in construction methods

Carbon fiber sheeting offers a relatively flexible construction method. During the reinforcement process, the sheet is first fixed to the surface being reinforced using an adhesive or impregnated adhesive. After curing, it forms a reinforced layer that adheres tightly to the structure. Carbon fiber sheeting is suitable for reinforcing various structural surfaces, and the construction process is relatively simple, requiring no extensive equipment.

The construction process of carbon fiber panels is relatively complex, typically requiring prefabrication in a factory and then transport to the construction site for installation. During installation, the panels are securely attached to the reinforced structure by drilling holes or using adhesives. Due to their high rigidity, their construction requires specialized equipment and techniques.

3.Different applicable scenarios

Due to its softness and adaptability, carbon fiber cloth is more suitable for scenarios that require flexibility, such as reinforcing cracks, resisting bending deformation, or improving the seismic performance of structures. It can fit tightly onto uneven surfaces for local reinforcement.

Carbon fiber panels are more suitable for scenarios where increased overall stiffness and strength are required. For example, in the reinforcement of long-span structures, carbon fiber panels can effectively control the deflection and deformation of the structure, improving its overall stability.

In practical applications, the choice between carbon fiber cloth and carbon fiber plate requires comprehensive consideration of the specific reinforcement situation and requirements. If overall stiffness needs to be increased, carbon fiber plate should be chosen; if local reinforcement is needed to accommodate curved surfaces or irregular structures, carbon fiber cloth is more suitable. Furthermore, a comprehensive assessment should be made based on factors such as project budget and construction schedule to select the most appropriate carbon fiber reinforcement material to ensure the reliability and durability of the reinforcement.

Ant Carbon can customize for any size and thickness of carbon fiber sheets and tubes.

A: Yes, we are absolutely welcome to buy sample order to test and check quality.

A: Absolutely. Our UV-resistant coatings prevent degradation, ensuring over 10 years of outdoor service life.

A: Designing parts for CNC machining involves several key considerations to ensure optimal manufacturability and quality. Here's a detailed breakdown of each aspect:

1. Simplicity: Keep designs as simple as possible to minimize machining time and cost.

2. Tolerances: Understand the machining tolerances of the CNC machine being used and design accordingly.

3. Tool Access: Ensure that tools can easily access all areas of the design for machining.

4. Material Selection: Choose materials based on the part's function, mechanical properties, and machining capabilities.

5. Minimize Internal Corners and Sharp Edges: Internal corners and sharp edges can be challenging to machine and may increase the risk of tool breakage. Minimize these features to facilitate tool movement and improve machining efficiency.

6. Uniform Wall Thickness: Design parts with uniform wall thickness to prevent warping and distortion during machining.

7. Fillets and Chamfers: Incorporate fillets and chamfers into your design to reduce stress concentrations and improve part strength.

8. Consider CNC Machine Size and Capabilities

Standard tolerances vary but typically range from ±0.005" (±0.127mm) to ±0.001" (±0.025mm) depending on the material and size of the part.

Yes, CNC machining can produce complex shapes. However, the more complex the design, the more time and resources are required, potentially increasing costs.

CNC machining is a subtractive process, removing material to create parts, while 3D printing is additive, building parts layer by layer. CNC machining is generally faster for producing metal parts and is superior in terms of strength and finish.

Yes, CAD (Computer-Aided Design) software is essential for designing parts for CNC machining. It helps in creating precise 3D models, which can then be translated into instructions for the CNC machine.

AI and machine learning can optimize machining processes, predict maintenance needs, and improve quality control, leading to increased efficiency and reduced costs.How Do I Choose a CNC Machining Service?When choosing a CNC machining service, consider their expertise, machinery capabilities, quality control processes, turnaround time, and cost.Can Small Quantities Be Produced Economically?Yes, CNC machining is suitable for small quantity production, especially for complex parts where mold or tooling costs for other manufacturing methods would be prohibitive.

STEP (Standard for the Exchange of Product model data) is an ISO standard exchange format used for representing 3D objects. It encodes detailed 3D data and is widely supported across different CAD software. STEP files are advantageous in CNC machining for several reasons:

Compatibility: STEP files are universally compatible with almost all CAD/CAM software.

Detail: They retain all the geometric and dimensional data of a part, essential for precision machining.

Flexibility: They can be easily edited, making them ideal for iterative design processes.

Carbon fiber CNC machining can provide a range of processing capabilities, including:

1. Cutting: CNC machines can precisely cut carbon fiber sheets into desired shapes and sizes according to CAD designs.

2. Drilling: Holes of various diameters can be accurately drilled into carbon fiber components for assembly or attachment purposes.

3. Milling: CNC milling can be used to create complex shapes and contours on carbon fiber parts with high precision.

4.Routing: Similar to milling, routing involves removing material from the carbon fiber using a rotating cutting tool to achieve specific shapes or profiles.

5. Engraving: CNC machines can engrave patterns, logos, or serial numbers onto carbon fiber surfaces for identification or branding purposes.

Don't miss any updates or promotions by signing up to our newsletter.