Typical characteristics and main applications of 10 common types of carbon fiber products.

- Dec-10-2025

- (29) Views

Continuous filament yarn

Product Features: The most common product form from carbon fiber manufacturers, the fiber bundle consists of thousands of individual filaments and is divided into three types according to the twisting method: NT (Never Twisted), UT (Untwisted), and TT or ST (Twisted). NT is the most commonly used type of carbon fiber.

Main Applications: Primarily used in composite materials such as CFRP, CFRTP, or C/C composites, with applications including aircraft/aerospace equipment, sporting goods, and industrial equipment parts.

2.Staple fiber yarn

Product Features: Also known as short-staple yarn, it is a yarn spun from short carbon fibers. For example, general-purpose pitch-based carbon fibers are typically in short fiber form.

Main Applications: Thermal insulation materials, friction-reducing materials, C/C composite parts, etc.

3.Carbon fiber fabric

Product Features: Made from continuous carbon fibers or short carbon fiber yarns through weaving. According to the weaving method, carbon fiber fabrics can be divided into woven fabrics, knitted fabrics, and non-woven fabrics. Currently, woven fabrics are commonly used for carbon fiber fabrics.

Main Uses: Similar to the uses of continuous carbon fibers, it is mainly used in composite materials such as CFRP, CFRTP, or C/C composites. Application areas include aircraft/aerospace equipment, sporting goods, and industrial equipment parts.

4.Carbon fiber braided tape

Product features: It belongs to a type of carbon fiber fabric, and is made by weaving continuous carbon fibers or short carbon fiber yarns.

Main uses: It is mainly used as a resin-based reinforcing material, and is especially suitable for the production and processing of tubular products.

5.Chopped Carbon Fiber

Product Features: Unlike the concept of short carbon fiber filaments, it is usually prepared from continuous carbon fibers through a chopping process. The chopped fiber length can be customized according to customer requirements.

Main Uses: It is commonly used as a filler in plastics, resins, cement, etc. By incorporating it into the matrix, it can improve mechanical properties, wear resistance, electrical conductivity, and heat resistance. In recent years, chopped carbon fiber has been the primary reinforcing fiber used in 3D printed carbon fiber composite materials.

6.Grinding carbon fiber

Product Features: Due to carbon fiber being a brittle material, it can be processed by grinding to produce powdered carbon fiber material, also known as ground carbon fiber.

Main Uses: Similar to chopped carbon fiber in its applications, but rarely used in cement reinforcement; typically used as a filler in plastics, resins, and rubber to improve the mechanical properties, wear resistance, electrical conductivity, and heat resistance of the base material.

7.Carbon fiber felt

Product Features: The main forms are felt or mats, prepared by first layering short fibers through mechanical carding and other methods, and then using a needle-punching process; also known as carbon fiber non-woven fabric, it is a type of carbon fiber textile.

Main Applications: Thermal insulation materials, base material for molded thermal insulation materials, base material for heat-resistant protective layers and corrosion-resistant layers, etc.

8.Carbon Fiber Paper

Product Features: Made from carbon fibers using dry or wet papermaking processes.

Main Applications: Antistatic boards, electrodes, loudspeaker cones, and heating plates; recent popular applications include positive electrode materials for new energy vehicle batteries.

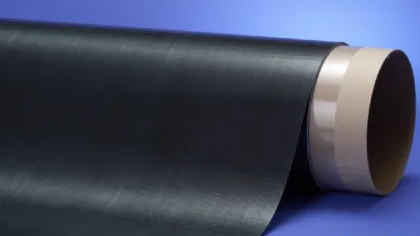

9.Carbon Fiber Prepreg

Product Features: A semi-cured intermediate material made from carbon fibers impregnated with thermosetting resin. It boasts excellent mechanical properties and a wide range of applications. Carbon fiber prepreg width is determined by the processing equipment size; common specifications include 300mm, 600mm, and 1000mm widths.

Main Applications: Fields requiring lightweight and high-performance materials, such as aircraft/aerospace equipment, sporting goods, and industrial equipment.

10.carbon fiber composite

Product Features: An injection-molded material made from a mixture of thermoplastic or thermosetting resin and carbon fibers. This mixture is created by adding various additives and chopped fibers, followed by a compounding process.

Main Applications: Due to the material's excellent electrical conductivity, high rigidity, and lightweight properties, it is primarily used in products such as casings for office automation equipment.

English

English