Major defects and optimization in the processing of composite material panels

- Feb-04-2026

- (7) Views

Major Defects in Composite Material Processing

Delamination: This is the most prominent problem in hole machining, especially prone to occur in the exit area where the drill bit is about to penetrate the bottom layer of the workpiece. At this point, the uncut material bends and deforms under axial force. When the interlayer stress exceeds the bond strength, delamination occurs. Excessive feed rate, tool wear, and improper tool geometry are the main contributing factors.

Fiber Pull-out: Due to weak bonding between the fiber and the matrix interface, or an insufficiently sharp tool, the fiber is not cut but pulled out of the matrix as a whole, leaving holes or rough cross-sections on the machined surface, severely affecting surface quality and bond strength.

Matrix Thermal Damage: Excessively high cutting temperatures cause damage to the resin's chemical structure. For thermosetting composites, this manifests as matrix charring, discoloration, and smoke production; for thermoplastic composites, it manifests as matrix melting and resolidification, forming nodules. Thermal damage significantly reduces the mechanical properties of the material.

Burrs/Fringes: At the hole exit or edge, fibers are not completely cut and become bent and fluffy, forming burrs. Fiber tearing may also occur at milled edges. This is mainly related to tool sharpness, fiber orientation, and cutting parameters.

Hole Dimensional Error: This includes hole shrinkage and expansion. Shrinkage often stems from the elastic recovery of the composite material; while expansion is mostly caused by tool runout, vibration, or insufficient rigidity of the machining system, which is particularly complex when drilling multilayer composite materials (such as CFRP and titanium alloy laminates).

Optimization direction

1. Application of Special Cutting Tools

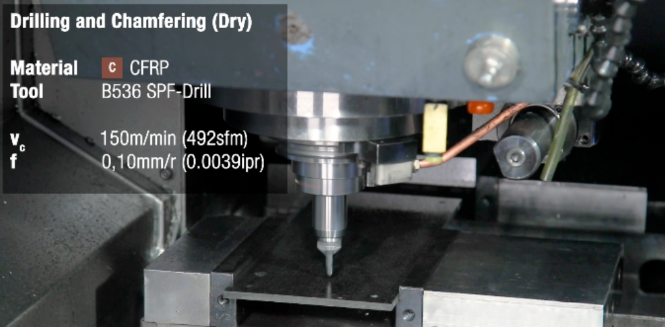

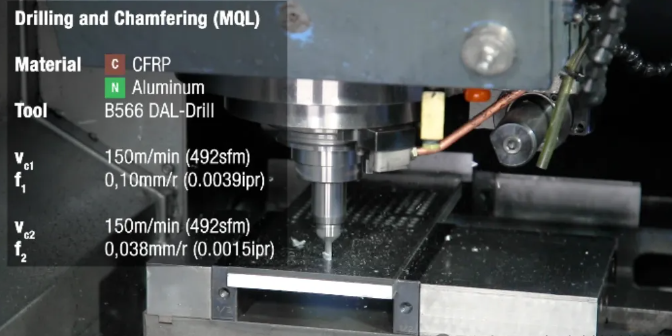

Geometric Design: Drills employing special geometries, such as double-angle (DAL) drills, three-pointed drills (candle wick drills), or split-fiber (SPF) drills. These designs help reduce axial thrust, achieving a clean "cut-then-expand" cutting process and effectively suppressing delamination and burrs at the exit.

Tool Materials and Coatings: Polycrystalline diamond (PCD) tools, due to their extremely high hardness and wear resistance, are ideal for machining carbon fiber composites, especially those containing abrasive fibers. Diamond coatings can also significantly improve the life of carbide tools. A sharp cutting edge and a low coefficient of friction are crucial for reducing heat and delamination.

2. Precision Control of Machining Parameters

Cutting Speed and Feed Rate: A high-speed, low-feed strategy is typically employed. High speed helps reduce single-edge cutting force, but care must be taken to avoid excessive speed causing resin thermal damage. Low feed significantly reduces axial force and is the most direct and effective means of controlling delamination, but it sacrifices efficiency. A balance between efficiency and quality needs to be found.

Peck Drilling: For deep holes or easily delaminated materials, a peck drilling cycle—where the drill bit feeds in segments and periodically retracts for chip breaking and heat dissipation—effectively removes chips from the hole, reducing heat accumulation and secondary scratching of the hole wall by chips. This is particularly suitable for drilling laminated materials.

3. Integration of Advanced Auxiliary Technologies

Cooling Strategy: Given the heat sensitivity of composite materials, traditional cast-in-place coolants may affect material properties by seeping into the laminate. Micro-volume lubrication (MQL) and cryogenic cooling (such as liquid carbon dioxide) are becoming more preferred solutions. They can act precisely on the cutting zone with minimal cooling medium usage, effectively reducing temperature and friction.

Support and Process Rigidity: Using rigid backing supports on the workpiece exit side can greatly suppress material deformation and is the most effective physical method to prevent exit delamination. Simultaneously, ensuring high rigidity of the machine tool-fixture-tool system reduces vibration and improves hole accuracy and surface quality.

English

English