Filament Winding and Spray Lay-up

- Dec-17-2025

- (28) Views

Filament Winding

1.1 Process Concept

This process is primarily used for hollow, typically circular or elliptical components, such as pipes and storage tanks. The fiber bundles are passed through a resin bath before being wound onto a mandrel. The rotation speed of the mandrel is controlled by the fiber delivery mechanism and the mandrel's orientation.

1.2 Main Materials

The resin matrix can be any type, such as epoxy resin, polyester, vinyl ester, or phenolic resin, and there are no restrictions on the fiber type. However, the fibers are taken directly from the bobbin stand and are not woven into a fabric.

1.3 Main Advantages

i) This is a very fast and economical method for laying down materials.

ii) The resin content can be controlled by measuring the resin passing through the chuck or mold on each fiber bundle.

iii) Fiber costs are minimized because there is no second process of transforming the fibers into fabric before use.

iv) The structural properties of the laminate can be excellent because the straight fibers can be laid in complex patterns to match the applied loads.

Spray Lay-up

2.1 Process Concept

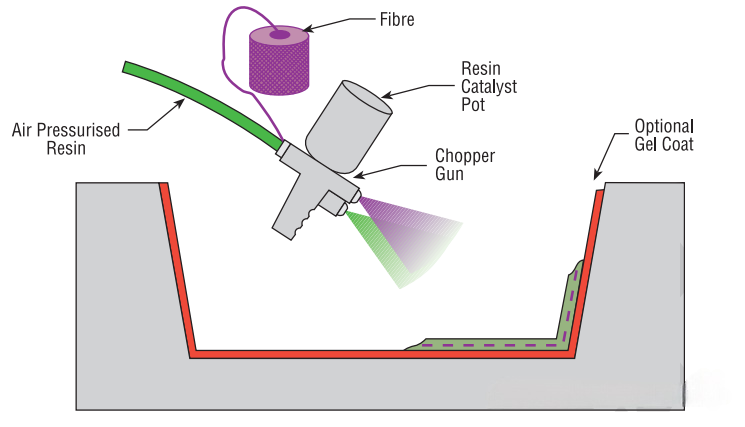

Fibers are chopped in a handheld gun and then fed into a catalytic resin spray directed at a mold. The deposited material cures under standard atmospheric conditions (as shown in Figure 2).

2.2 Main Materials

The resin matrix is primarily polyester resin, and the fiber material is limited to glass fiber roving.

2.3 Main Advantages

i) Widely used for many years.

ii) Fast method for depositing fibers and resin.

iii) Low cost.

2.4 Main Disadvantages

i) Laminates tend to be resin-rich, resulting in excessive weight.

ii) Only contains short fibers, severely limiting the mechanical properties of the laminate.

iii) The resin requires low viscosity for spraying, which often compromises its mechanical/thermal properties.

iv) High styrene content in spray resins usually means they are more hazardous, and their lower viscosity means they have a greater tendency to penetrate clothing, etc.

v) Limiting the concentration of styrene in the air to legal levels is becoming increasingly difficult.

2.5 Typical Applications

Simple casings, lightly loaded structural panels, such as caravan bodies, truck fairings, bathtubs, shower trays, and some small boats.

English

English