Wet Lay-up and Vacuum Bagging

- Dec-18-2025

- (22) Views

Wet Lay-up

Process Concept

The process involves manually impregnating fibers, in the form of woven, knitted, stitched, or bonded fabrics, with resin. This is typically done using rollers or brushes, and increasingly, roller-type impregnators are used, where the resin is pressed into the fabric by rotating rollers and a resin bath. The laminate then cures under standard atmospheric conditions.

1. Main Materials

The resin matrix can be any type, including epoxy resin, polyester, vinyl ester, or phenolic resin, and there are no restrictions on the fiber type.

2. Main Advantages

i) Widely used for many years.

ii) Lower cost if using room-temperature curing resins.

iii) Wide range of suppliers and material types available.

iv) Higher fiber content and longer fiber lengths are possible.

3. Main Disadvantages

i) Resin mixing, resin content in the laminate, and laminate quality are highly dependent on the laminator's skill. It is often difficult to obtain low resin content laminates without introducing excessive voids.

ii) Health and safety concerns regarding the resins. The lower molecular weight of resins used in hand lay-up typically means they are more hazardous than higher molecular weight products. Lower viscosity resins also tend to penetrate clothing, etc.

iii) Without expensive extraction systems, it is increasingly difficult to limit the concentration of styrene in the air from polyester and vinyl ester resins to legal levels.

iv) Resins require low viscosity for manual application. This often compromises their mechanical/thermal properties due to the need for high concentrations of diluents/styrene.

4. Typical Applications

Standard wind turbine blades, production vessels, architectural decorative profiles, etc.

Vacuum Bagging

1.Process Concept

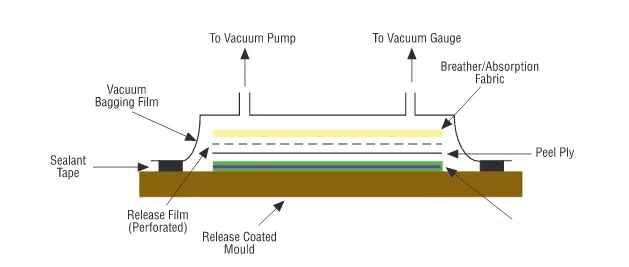

This process is essentially an extension of the wet lay-up process described above, where pressure is applied to the laminated material after lamination to improve its consolidation. This is achieved by sealing a plastic film over the wet lay-up laminate and the tool. The air under the bag is evacuated by a vacuum pump, thus allowing up to one atmosphere of pressure to be applied to the laminate for curing.

2 Main Materials

The resins primarily consist of epoxy and phenolic resins, while polyester and vinyl ester may present certain problems due to the vacuum pump excessively extracting styrene from the resin. For reinforcing fibers, the presence of consolidation pressure means that various heavy fabrics may become wet.

3 Main Advantages

i) Higher fiber content laminates can typically be achieved compared to standard wet lay-up techniques.

ii) Lower void content compared to wet lay-up.

iii) Better fiber wetting due to pressure and resin flow within the structural fibers, with excess resin entering the bagging material.

iv) Health and safety: Vacuum bagging reduces the amount of volatile organic compounds released during curing.

4.Main Disadvantages

i) The additional process increases labor and disposable packaging material costs.

ii) Operators require a higher level of technical skill.

iii) Resin content mixing and control still largely depend on the operator's skill.

iv) Although vacuum bagging reduces volatile organic compounds, exposure levels are still higher than prepreg processing techniques, etc.

Typical Applications

Large one-off cruising boats, racing car components, core bonding assemblies in production boats.

English

English