Carbon fiber spinning methods (wet spinning and dry-jet wet spinning)

- Jan-09-2026

- (48) Views

Currently, the production process of PAN-based carbon fibers mainly includes four major steps: polymerization, spinning, pre-oxidation, and carbonization. Each step has its own unique process characteristics and influences the others, jointly determining the performance and quality of the final carbon fiber. In the production process of PAN-based carbon fibers, the preparation of the precursor fiber plays a leading and decisive role.

The spinning processes for PAN fibers mainly include dry spinning, melt spinning (plasticized spinning), wet spinning, and dry-jet wet spinning.

Wet spinning

Wet spinning is currently the most widely used and technologically mature spinning method in industrial production.

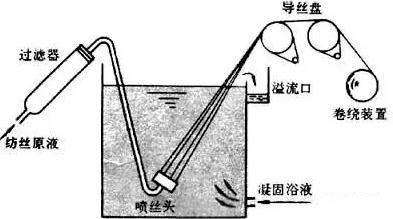

After the spinning solution is extruded, it directly enters the coagulation bath for material diffusion to form PAN fibers. Wet spinning uses spinnerets with small pore diameters, resulting in PAN fibers with smaller fineness and lower solvent residue; the large number of pores leads to high production capacity. However, the low concentration of the spinning solution and the low spinning speed can easily cause fiber breakage at the spinneret.

Furthermore, because extrusion swelling and coagulation molding occur simultaneously in wet spinning, the coagulation drawing is negative drawing, and the double diffusion process is relatively intense, leading to a severe core-shell structure in the fibers, with obvious grooves on the surface and numerous internal pores. This limits the strength of the PAN precursor fibers and prevents fundamental improvement in the quality of the precursor fibers and carbon fibers. Therefore, it is not suitable for preparing high-strength carbon fibers.

In wet spinning, the spinning solution is directly immersed in the coagulation liquid after exiting the spinneret. The process is simple and easy to control.

Carbon fibers produced by wet spinning have grooves arranged along the fiber axis on their surface. These grooves increase the surface area of the carbon fibers, which is beneficial for the physical interlocking between the carbon fibers and the resin, improving the interfacial bonding performance of the composite material. However, these grooves are also defects on the surface of the carbon fibers. If the grooves vary in depth, stress concentration can easily occur, affecting the tensile strength of the carbon fibers.

Currently, wet spinning has low efficiency.

Dry-jet wet spinning

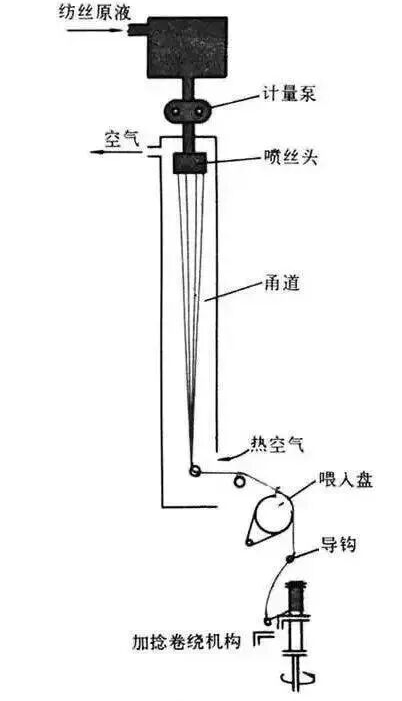

Dry-jet wet spinning combines the advantages of both dry spinning and wet spinning, making it an ideal spinning method for obtaining PAN precursor fibers and carbon fibers with dense structures and excellent mechanical properties. Unlike wet spinning, in dry-jet wet spinning, the spinning solution is extruded through the spinneret holes and does not directly enter the coagulation bath, but instead passes through an air layer before solidifying into fibers in the coagulation bath. The presence of the air layer allows a dense film to form on the surface of the PAN filament, which helps to suppress the double diffusion process and the formation of pores inside the fiber; at the same time, the fiber surface is relatively smooth, with almost no grooves. Dry-jet wet spinning uses larger spinneret diameters and faster spinning speeds, 5-6 times faster than wet spinning; it is suitable for high molecular weight and high concentration spinning solutions, and the coagulation drawing is positive drawing. The precursor fibers prepared by this process have a smooth surface, uniform cross-section, small differences in core-shell structure, fewer defects, high density, and excellent mechanical properties, which are conducive to the preparation of high-strength PAN-based carbon fibers. It has been widely used in industrial production, and a representative company in China that has mastered the key production technology of dry-jet wet spinning is Ant Carbon Fiber Composite Materials Co., Ltd. However, a major disadvantage of dry-jet wet spinning is that the spinning solution is prone to spreading, thus limiting the increase in the number of holes on a single spinneret plate, and restricting the single-line production capacity; in addition, the smooth surface of the fibers prepared by dry-jet wet spinning can lead to poor interfacial bonding when used as a reinforcing phase in composite materials, requiring special treatment.

Dry-jet wet spinning is a method where the spinning solution flows out of the spinneret, passes through air, and then immerses into the coagulation liquid. This method offers fast spinning speed, dense fibers, and a smooth surface, with optimized orientation of polyacrylonitrile (PAN) molecular chains along the fiber direction, resulting in higher tensile strength. However, a disadvantage of dry-jet wet spinning is that the smooth surface weakens interfacial bonding, leading to low interlaminar shear strength (ILSS), which reduces the mechanical properties of the composite material. Also, grooves can easily retain organic solvents, causing internal defects in the precursor fibers and affecting fiber quality. However, dry-jet wet spinning is fast.

English

English