What is autoclave molding process?

- Jan-16-2026

- (37) Views

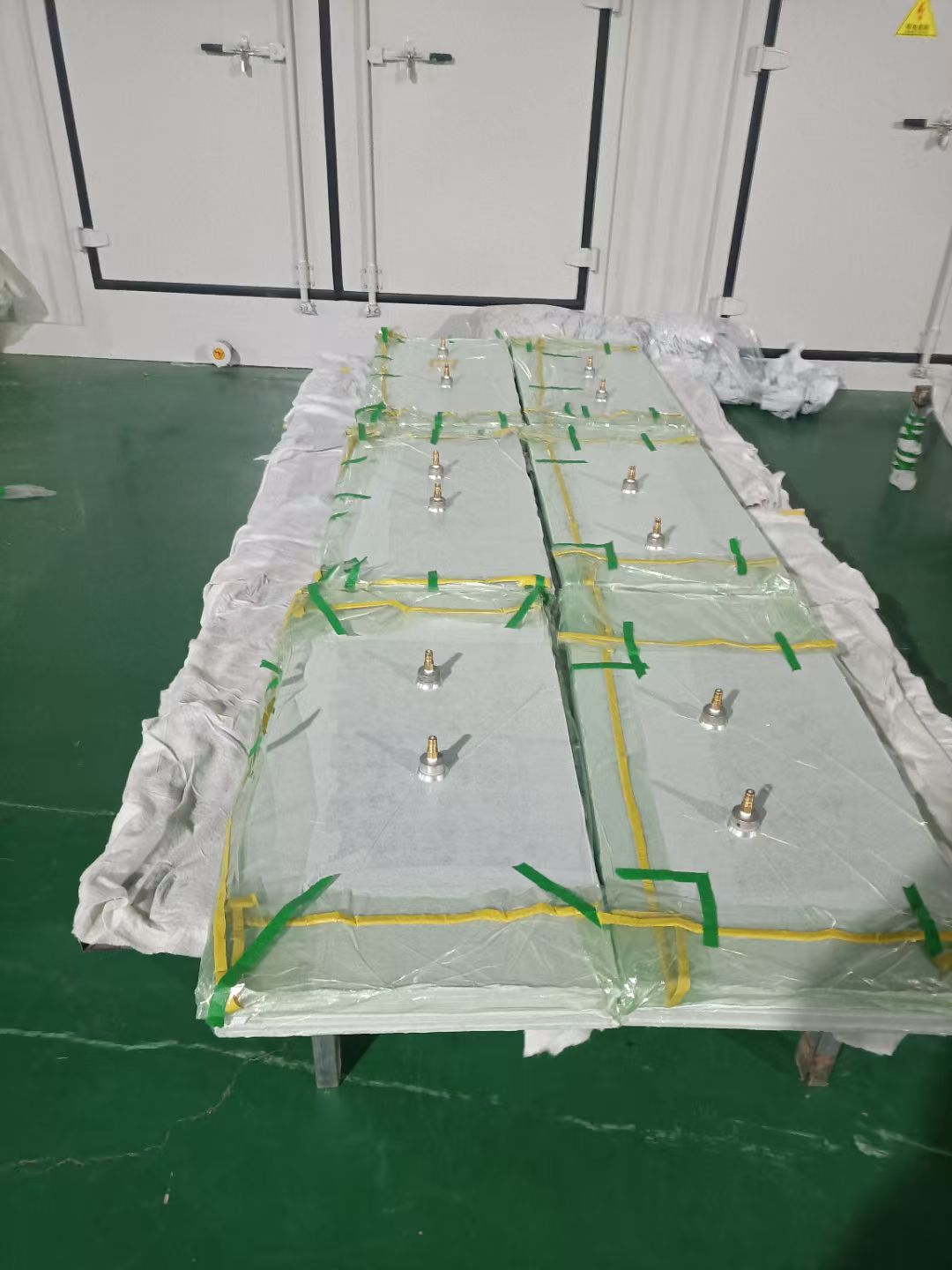

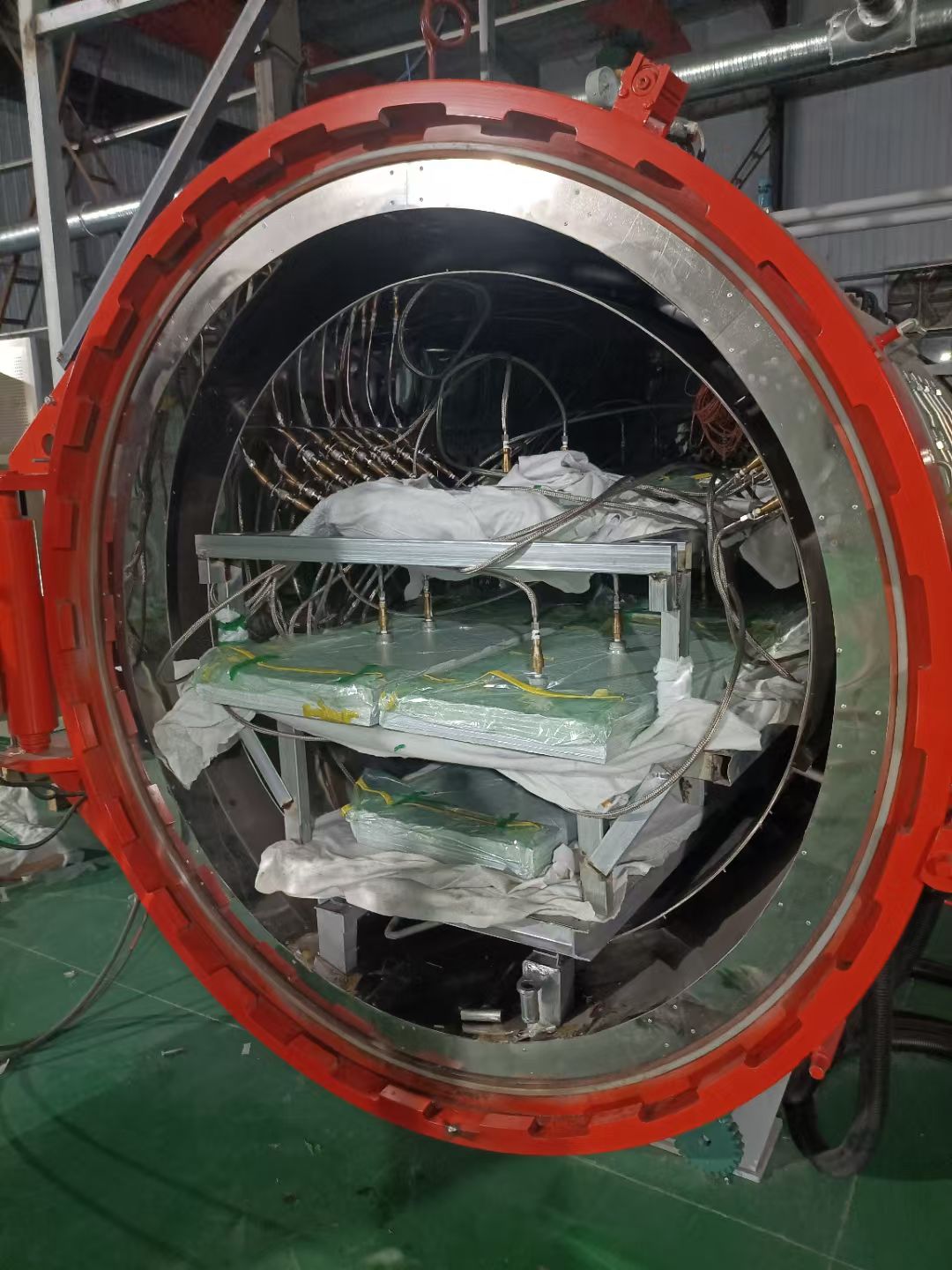

Autoclave processing refers to a manufacturing method where prepreg materials are laid onto a mold according to the required layup sequence, sealed in a vacuum bag, and then placed in an autoclave. The autoclave then heats and pressurizes the materials, completing the curing reaction and forming the prepreg workpiece into the desired shape while meeting quality requirements.

Prepreg: This is a composite material made by impregnating continuous fibers or fabrics with a resin matrix under strictly controlled conditions. It is an intermediate material used in the manufacture of composite materials.

Autoclave: An autoclave is a specialized pressure vessel capable of withstanding and controlling a range of temperatures and pressures. It is a process equipment specifically designed for the characteristics of polymer-based composite material molding processes.

Autoclave Process Flow: 1. Select pre-impregnated carbon fiber fabric and cut it using automatic cutting equipment. 2. Apply 3-7 layers of carbon fiber prepreg to the mold surface. 3. Lay vacuum assist materials. 4. Seal the vacuum bag, evacuate the air, and perform a pressure test. 5. Place the mold in the autoclave and heat it to approximately 130 degrees Celsius under a vacuum pressure of 0.6 MPa to 1.0 MPa for 2-4 hours to cure and form the product.

Advantages of Autoclave Process: Uniform pressure inside the autoclave: Compressed air, inert gas (N2, CO2), or a mixed gas is used to pressurize the autoclave. The pressure acting on the normal of each point on the vacuum bag surface is the same, ensuring that the component is molded and cured under uniform pressure;

Uniform air temperature inside the autoclave: The heating (or cooling) gas circulates at high speed inside the autoclave, resulting in essentially uniform gas temperature at all points inside the autoclave. Provided the mold structure is reasonable, this ensures that the temperature difference between different points of the component sealed in the mold is minimal during heating and cooling;

This process provides better quality and consistency: Components manufactured using the autoclave process have lower porosity and uniform resin content. Compared to other molding processes, parts prepared using the autoclave process have stable and reliable mechanical properties. Carbon fiber products manufactured using the autoclave process have very high strength and hardness (three times the hardness of steel), and are also very lightweight.

Maintains the perfect appearance of the carbon fiber fabric: In the autoclave process, all carbon fiber surface textures are free from any misalignment or damage, resulting in a very complete and aesthetically pleasing carbon fiber surface.

Wide range of applications: The temperature and pressure conditions of the autoclave can meet the molding process requirements of almost all polymer-based composite materials. It is the main method for manufacturing continuous fiber-reinforced composite parts. To date, the aerospace industry and high-performance vehicles such as supercars all utilize the autoclave process.

English

English