How to choose between unidirectional and bidirectional carbon fiber cloth?

- Nov-07-2025

- (20) Views

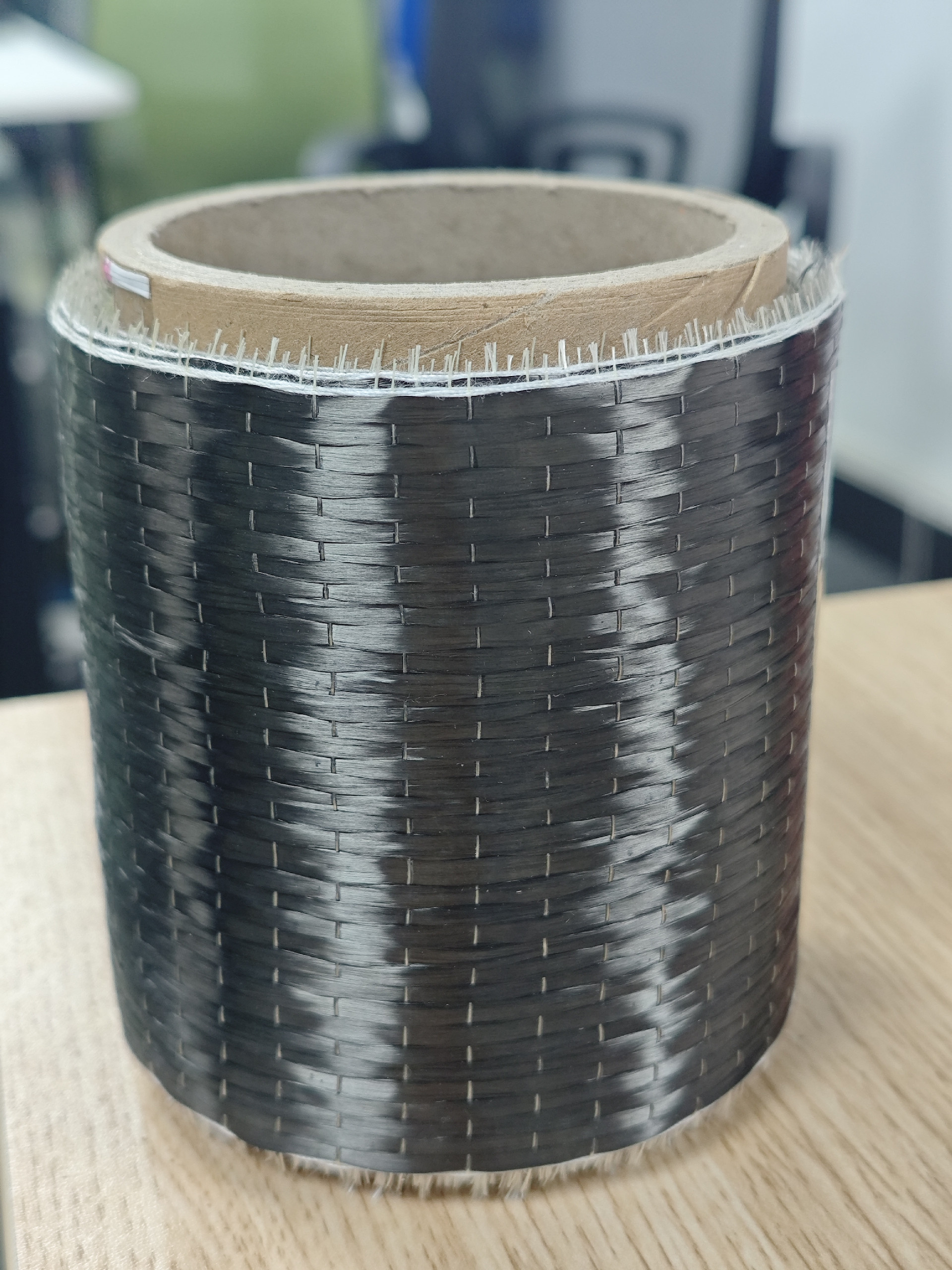

Unidirectional carbon fiber cloth

Unidirectional carbon fiber cloth has a large number of carbon fiber bundles arranged in one direction (usually the warp), while only a small number of fine fibers or special hot melt adhesive threads are used for fixing in the other direction. This structure makes its strength mainly concentrated in the direction in which the carbon fiber bundles are arranged.

Advantage

1. Ultra-high directional strength: Unidirectional carbon fiber fabric possesses extremely high tensile strength in its fiber alignment direction, typically several times that of ordinary steel.

Taking unidirectional fabric woven from common 12K carbon fiber filaments as an example, it can easily withstand enormous tensile forces in its dominant direction, making it suitable for scenarios requiring extremely high strength in specific directions, such as the reinforcement of tension zones in beams and slabs in building structures.

2. Excellent impregnation: Due to its relatively simple structure, unidirectional carbon fiber fabric exhibits excellent wetting properties with its matching carbon fiber adhesive.

During construction, the adhesive can quickly and evenly penetrate into the fiber gaps, allowing the carbon fiber fabric to bond tightly to the reinforced substrate, forming a robust composite that effectively transfers stress.

3. Relatively low cost: Compared to bidirectional carbon fiber fabric, unidirectional carbon fiber fabric has a simpler production process and uses less raw material, resulting in a lower overall cost. This gives it a cost advantage in large-scale conventional reinforcement projects, making it highly cost-effective.

4. Convenient Construction: Unidirectional carbon fiber cloth is soft and can be cut to any size according to actual needs. During construction, it can be simply pasted along the tensile direction or perpendicular to the crack direction.

No complicated operating skills or large construction equipment are required, which greatly shortens the construction cycle and makes it easy to ensure the construction quality. Even if the surface of the object to be reinforced is uneven, a high effective adhesion rate can be guaranteed.

If air bubbles appear on the pasted surface, they can be easily solved by injecting adhesive with a syringe.

Disadvantage

1. Weak performance in non-dominant directions: Unidirectional carbon fiber cloth exhibits lower strength in the direction perpendicular to the carbon fiber filament arrangement, resulting in poor resistance to tensile and shear forces.

If the structure is subjected to complex forces in multiple directions, using only unidirectional carbon fiber cloth may not fully meet the reinforcement requirements, presenting certain limitations.

2. Increased risk of breakage: When the direction of the external force is inconsistent with the direction of the carbon fiber filament arrangement, unidirectional carbon fiber cloth is more prone to breakage or damage.

For example, in structural parts subjected to irregular forces, using unidirectional cloth for reinforcement may lead to carbon fiber cloth failure if subjected to forces from unexpected directions, affecting the reinforcement effect.

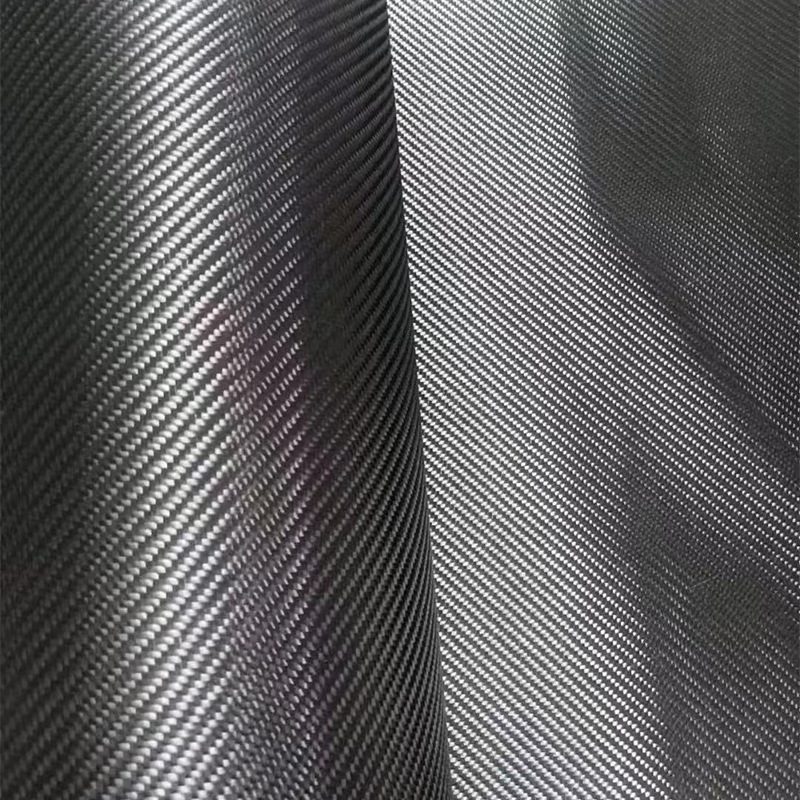

Bidirectional carbon fiber cloth

Biaxially oriented carbon fiber fabric contains a large amount of untwisted roving in both the transverse and longitudinal directions, and is woven in both warp and weft directions. Its texture is diverse, with common patterns including plain weave, twill weave, and satin weave. This structure gives it relatively balanced mechanical properties in both directions.

Advantages

1. Excellent bidirectional load-bearing capacity: It can withstand tensile and compressive forces from different directions, avoiding the disadvantage of unidirectional carbon fiber cloth being subjected to force in only one direction.

In structures with complex stress directions and where the main stress direction is difficult to determine, bidirectional carbon fiber cloth can provide a more comprehensive and uniform reinforcement effect, significantly improving the overall stability and load-bearing capacity of the structure.

2. Adaptability to complex shapes: Due to the characteristics of bidirectional weaving, bidirectional carbon fiber cloth has good flexibility and can better conform to irregularly shaped structural surfaces, such as pipes and irregularly shaped building components.

When reinforcing these special structures, bidirectional carbon fiber cloth can tightly wrap them, fully exerting its reinforcement effect and ensuring that all parts of the structure are effectively strengthened.

3. Wide range of applications: With its excellent bidirectional load-bearing capacity and ability to conform to complex shapes, bidirectional carbon fiber cloth is not only suitable for reinforcing building structures, but also widely used in industrial equipment, aerospace, and other fields.

For example, in manufacturing industrial parts that need to withstand multidirectional stress and some structural components of aerospace vehicles, bidirectional carbon fiber cloth can meet the requirements for high-performance materials.

Disadvantages:

1. Relatively Lower Strength: Although biaxial carbon fiber fabric exhibits good performance in both directions, its strength in each direction is slightly lower than that of uniaxial carbon fiber fabric in its dominant direction.

This is because the interweaving and overlapping of each carbon fiber filament during weaving disperses the fiber strength to some extent, preventing it from achieving the ultra-high strength of uniaxial carbon fiber fabric in any single direction.

2. Complex Weaving Process and High Cost: The weaving process for biaxial carbon fiber fabric is more complex, requiring precise control of the interweaving of carbon fiber bundles in both warp and weft directions.

This places higher demands on production equipment and processes. This results in relatively lower production efficiency and greater raw material waste, leading to a significantly higher price for biaxial carbon fiber fabric compared to uniaxial carbon fiber fabric. In cost-sensitive projects, this may limit its large-scale application.

3. Difficult Impregnation: Due to the relatively thick thickness and complex internal fiber interweaving of biaxial carbon fiber fabric, the impregnation process with the matching carbon fiber adhesive is more challenging.

The glue cannot penetrate into the gaps between each fiber quickly and evenly, which may affect the bonding effect between the carbon fiber cloth and the substrate, and thus affect the reinforcement quality. This places higher demands on the construction process and the technical level of the operators.

How to Choose?

The choice between unidirectional and bidirectional carbon fiber fabric depends on the specific application scenario and structural stress characteristics. If the structural stress direction is clear, with significant tensile force mainly occurring in one direction,

such as the reinforcement of common building beams and slabs for bending resistance, then unidirectional carbon fiber fabric is the preferred choice due to its extremely high directional strength and good cost-effectiveness. However, if the structural stress is complex, with stress in multiple directions, or if the shape is irregular,

such as the reinforcement of irregularly shaped components in some ancient buildings or pipe repairs, then bidirectional carbon fiber fabric can better leverage its advantages in bidirectional stress distribution and its ability to conform to complex shapes.

English

English