What are aramid fiber composite materials?

- Nov-26-2025

- (10) Views

Aramid fiber, also known as poly(p-phenylene terephthalamide), possesses excellent properties such as ultra-high strength,

high modulus, high temperature resistance, acid and alkali resistance, and light weight.

It was successfully developed and commercialized by DuPont in the 1960s (trade name Kevlar).

Therefore, before the advent of carbon fiber, aramid fiber dominated the high-performance fiber market.

Characteristics of aramid fiber composite materials

2.1 High impact resistance and crack resistance

Aramid fibers possess excellent impact resistance and, due to their toughness and ability to absorb large amounts of energy, will not break under pressure.

They are widely used in the manufacture of bulletproof vests, armor for boats, kayaks, and military vehicle components.

The impact resistance of aramid fiber composites is five times that of carbon fiber composites (tested using the drop hammer impact method).

This extraordinary resistance to impact or bullets is caused by the long atomic chains that form the aramid structure.

Given their superior impact resistance, aramid fibers are widely used in military applications, such as in the manufacture of bulletproof vests and tank armor materials.

Bulletproof vests are typically made of dozens of layers of aramid (such as Kevlar) with a ceramic plate between the layers.

The protective shields used on some armored vehicles (such as the US M1 tank) are made of steel-aramid-steel materials and can withstand anti-tank missiles with a diameter of up to 700mm.

In addition to protecting the tank itself, the steel-aramid-steel shield also protects the crew by absorbing the kinetic energy generated by penetrating missiles.

Another application of Kevlar is on the Boeing AH-64, a US military main attack helicopter equipped with Kevlar rotors.

Here, Kevlar can stop bullets with a maximum diameter of 23 mm.

Due to its high impact resistance, Kevlar is widely used in the construction of boats and kayaks, such as the hulls designed for the Volvo Ocean Race, one of the most challenging sports.

Most high-performance kayaks for water sports are made of aramid fibers or carbon fiber/aramid fiber blends.

2.2 Low density/low weight

Aramid fibers possess extremely low weight, an advantage in the manufacture of composite materials.

While carbon fiber composites are considered very light,aramid fiber composites are approximately 20% lighter.

Using aramid fabrics in composites increases impact and abrasion resistance and reduces the weight of composite components.

The density of aramid fibers is approximately 1.45 g/cm³, while the density of aramid-epoxy composites is approximately 1.3 g/cm³.

This calculation is based on a mixed density of epoxy resin and curing agent of approximately 1.1 g/cm³,

and the advanced technology used in the composite production process, namely autoclave prepreg.

In contrast, carbon fiber composites, Generally considered very light, have a density close to 1.55 g/cm³.

Overall, aramid fiber composites are 20% lighter than carbon fiber composites.

How to compare the weight of aramid fiber composites with metals? Aluminum is 2.7 g/cm³, titanium is 4.5 g/cm³, and steel is 7.9 g/cm³.

Therefore, aramid fiber composites are twice as light as aluminum, three or four times lighter than titanium, and six times lighter than steel.

2.3 Moderate stiffness, between that of glass fiber and carbon fiber.

Aramid fiber composites exhibit higher stiffness than glass fiber composites, but significantly lower stiffness than carbon fiber composites.

Similar to carbon fiber, aramid fibers come in many types, including standard, medium, and high modulus fibers, offering varying degrees of stiffness and strength.

The stiffness of different fiber types is as follows:

Glass fiber fabrics – from 72 GPa (standard E-glass) to 87 GPa (S-reinforced glass fabrics);

Carbon fiber fabrics – from 230 GPa (Toray T300) to 588 GPa (Toray HM grade M60J);

Aramid fiber fabrics – from 96 GPa (standard aramid, i.e., Kevlar 129) to 186 GPa (aramid used in the aircraft/aviation industry, i.e., Kevlar 149).

In summary, aramid composites made from standard fabrics have 30-40% higher stiffness than glass fiber composites, but 50% lower stiffness compared to carbon fiber composites.

2.4 Abrasion Resistance

Aramid fiber composites are widely used in easily worn components, such as skid plates protecting racing car engines.

Aramid is commonly used in extraction industries (such as mining) to reinforce conveyor belt rubber belts,

ensuring higher strength and abrasion resistance; according to Kevlar manufacturers,reinforcement can improve abrasion resistance by 50-70%.

Due to these properties, the material can be used in composite materials and workwear, such as cut-resistant safety gloves using aramid fabrics, such as those from Twaron or Kevlar.

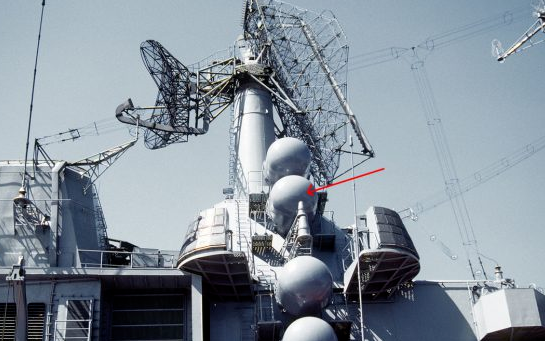

2.5 Low Dielectric Constant

The dielectric constant of aramid fiber composites is as low as ~3.85 (10 GHz), ensuring good signal penetration performance and strength through the aramid radome/antenna.

This type of antenna is widely used for military purposes, such as on military aircraft.

Aramid fiber composite shells/radomes protect antennas from damage and ensure good signal performance.

In contrast, E-glass fiber composites offer a capacitance of 6.1 (10 GHz), resulting in a 60% reduction in antenna signal power and performance.

In addition to aramid, quartz fiber is also used, with a dielectric constant of 3.78 (10 GHz).

2.6 Other Properties

Aramid fibers have low thermal expansion characteristics, are very stable at high temperatures (almost zero), and have a slightly negative coefficient of thermal expansion, equivalent to (-2.4 x 10⁻⁶ /°C). Aramid fibers are excellent insulators and are non-conductive.A particular property of aramid fiber composites is related to vibration absorption, making them suitable for manufacturing vibration-exposed components, such as aircraft structural parts.

2.7 Blending Composites with Other Fabrics

Aramid fiber fabrics can be parameter-tuned for use in carbon fiber and glass fiber composites, providing suppliers of composite products with a variety of possibilities.For carbon fiber composites, impact resistance can be improved by adding several layers of aramid fiber fabric. Hybrid composites composed of 50% carbon fiber

and 50% aramid fiber can improve impact resistance by up to 25% compared to composites made of carbon fiber alone.

English

English