Comparing Carbon Fiber and Fiberglass: Materials of the Future

- May-10-2025

- (119) Views

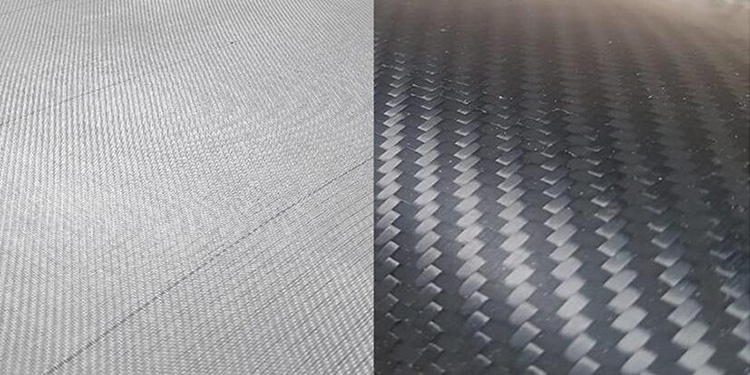

In the realm of materials science, the quest for lightweight, durable, and versatile substances has led to the development of numerous innovative materials. Among these, carbon fiber and fiberglass stand out as two prominent contenders, each with its own unique properties and applications. Let’s delve into the characteristics, benefits, and drawbacks of these materials to understand their comparative strengths and weaknesses.

Carbon Fiber:

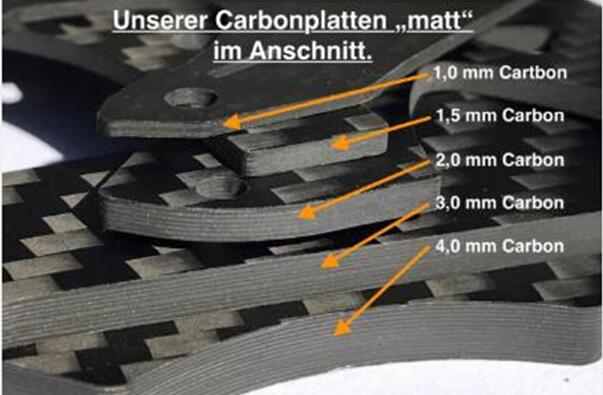

Carbon fiber is a composite material renowned for its exceptional strength-to-weight ratio, stiffness, and resistance to corrosion. It is composed of thin strands of carbon atoms bonded together in a crystal alignment, resulting in a material that is incredibly strong and lightweight.

Benefits of Carbon Fiber:

1. Strength and Stiffness: Carbon fiber exhibits impressive tensile strength, making it suitable for applications where rigidity and resilience are paramount. It excels in environments where high-performance materials are required, such as aerospace, automotive, and sports equipment.

2. Lightweight: One of carbon fiber’s most notable attributes is its low density. This characteristic makes it ideal for reducing weight in applications where mass is a critical factor, such as aircraft components and sports equipment.

3. Corrosion Resistance: Unlike metals, carbon fiber is impervious to corrosion, making it an excellent choice for outdoor and marine applications where exposure to moisture and harsh environments is a concern.

Drawbacks of Carbon Fiber:

1. Cost: Carbon fiber is relatively expensive compared to traditional materials like steel and aluminum. The manufacturing process, which involves precise weaving and resin infusion, contributes to its high cost.

2. Brittleness: While carbon fiber is exceptionally strong under tension, it can be brittle when subjected to impacts or compression forces. This brittleness necessitates careful design considerations to prevent structural failure.

Fiberglass:

Fiberglass, also known as glass-reinforced plastic (GRP), is a composite material composed of fine glass fibers embedded in a polymer matrix, typically epoxy or polyester resin. It is valued for its versatility, affordability, and ease of fabrication.

Benefits of Fiberglass:

1. Affordability: Fiberglass is generally more economical than carbon fiber, making it a preferred choice for applications where cost is a primary consideration. Its lower production costs make it accessible for a wide range of industries and applications.

2. Moldability: Fiberglass can be molded into complex shapes with relative ease, allowing for the production of intricate components and structures. This versatility makes it suitable for a diverse array of applications, from boat hulls to architectural panels.

3. Impact Resistance: Compared to carbon fiber, fiberglass exhibits greater resilience to impacts and flexing. This property makes it well-suited for applications where durability and toughness are essential, such as automotive body panels and recreational equipment.

Drawbacks of Fiberglass:

1. Weight: While fiberglass is lighter than many metals, it is generally heavier than carbon fiber. In applications where weight reduction is critical, fiberglass may not offer the same level of performance optimization as carbon fiber.

2. Strength: Although fiberglass is strong and durable, it typically has lower tensile strength and stiffness compared to carbon fiber. This limitation may restrict its suitability for high-performance applications where maximum strength-to-weight ratios are required.

Conclusion:

In summary, carbon fiber and fiberglass are two composite materials with distinct characteristics and applications. Carbon fiber excels in environments where superior strength, stiffness, and lightweight properties are paramount, albeit at a higher cost. On the other hand, fiberglass offers affordability, moldability, and impact resistance, making it a versatile choice for a wide range of applications. The selection between these materials depends on specific project requirements, budget considerations, and performance criteria, ultimately determining which material is best suited for the task at hand.

English

English