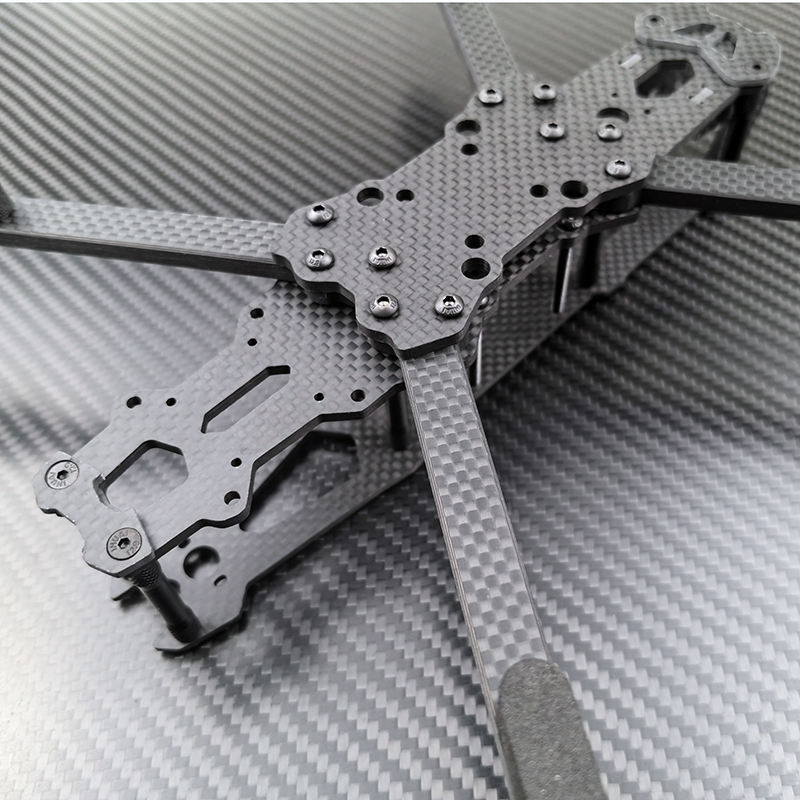

Application of Carbon Fiber Materials in Various Parts of Drones

- Nov-05-2025

- (112) Views

Currently, carbon fiber materials are widely used in the production and manufacturing of drones worldwide. The amount of carbon fiber materials used accounts for 60%-80% of the structure of drones. In the production and manufacturing of drones, carbon fiber materials are used in the fuselage frame, skin, wings and tail, landing gear, rotor and propeller, etc.

Which parts of a drone are made of carbon fiber?

Fuselage frame

The high specific strength and specific stiffness of carbon fiber composites can ensure the structural strength of the airframe while significantly reducing its weight, which is crucial for improving the endurance and flight-related performance of drones. When combined with unibody molding technology, the manufacturing process of drones can be simplified, overall structural stability improved, and payload capacity enhanced.

2.Skin

The skin of a drone not only protects its internal equipment but also significantly impacts its aerodynamic performance. Skin made of carbon fiber composite materials has a smooth surface, precise shape, and good symmetry, reducing air resistance and improving the drone's flight speed and efficiency. Furthermore, carbon fiber skin exhibits excellent fatigue resistance and durability, enabling it to withstand long-duration flight missions.

3.Wings and tail

Wings and tail fins are key components for generating lift and controlling flight attitude in drones, requiring high-performance materials. The high strength and lightweight characteristics of carbon fiber composites can provide sufficient lift and good handling performance for wings and tail fins. Furthermore, the anisotropic properties of carbon fiber can be used in a well-designed layup to meet the mechanical performance requirements of wings and tail fins in different directions, improving the flight stability and maneuverability of drones.

4.Landing gear

Landing gear is a critical component for drones during landing and needs to withstand enormous impact loads. Through rational structural design, such as using a honeycomb sandwich structure, carbon fiber composite materials not only reduce weight but also improve energy absorption and shock absorption capabilities, thus protecting the drone's safety during landing.

5.Rotor and propeller

For multi-rotor drones, rotors and propellers are crucial. By optimizing material formulations and molding processes, carbon fiber composites can be used to manufacture rotors and propellers that are both lightweight and robust, reducing air resistance and improving lift efficiency. At the same time, the fatigue resistance of carbon fiber composites ensures the stability and reliability of drones during long-duration flights.

6. Battery Box and Fuel Tank

Carbon fiber materials are also commonly used to manufacture components such as battery boxes and fuel tanks. Due to their lightweight, high strength, and corrosion resistance, they help reduce the overall weight of the UAV while ensuring the stable operation of these key components in harsh environments.

7.Connectors: The various components of a fixed-wing UAV need to be connected through connectors. Carbon fiber composite materials have excellent connection performance and can be firmly connected to other components through various connection methods (such as bolt connection, riveting, etc.), ensuring the overall structural stability of the UAV.

What are the main types of carbon fiber materials used in drone production?

The main carbon fiber materials used in drone manufacturing include carbon fiber fabrics and prepregs.

Carbon fiber fabrics, as the basic material for drone structural components, are renowned for their high strength, low weight, corrosion resistance, and excellent thermal stability. In drone manufacturing, carbon fiber fabrics are commonly used to make wings, fuselage frames, and other critical load-bearing components. This material not only effectively reduces the overall weight of the drone and improves flight efficiency, but also maintains structural stability and durability in extreme environments. Through precise cutting and sewing processes, carbon fiber fabrics can be processed into various shapes and sizes to meet the diverse design requirements of drones.

Carbon fiber prepreg is another important composite material in drone manufacturing. Prepreg is obtained by impregnating carbon fiber fabric with a specific type of resin matrix under strictly controlled conditions. After curing, this material can form structural components with high strength, high modulus, and good fatigue resistance. In drone production, carbon fiber prepreg is often used to manufacture complex structural components such as landing gear, engine mounts, and battery compartments. Through processes such as compression molding and autoclave curing, carbon fiber prepreg can be precisely machined into the required shapes, providing robust yet lightweight structural support for drones.

English

English