These application scenarios of carbon fiber hide what future life will look like

- Sep-12-2025

- (50) Views

1.Aerospace: The core assistant for weight reduction and safety

Core structures such as the fuselage, wings, and tail of spacecraft and aircraft have traditionally relied on metal materials.

However, metal is heavy and prone to corrosion, increasing fuel consumption and maintenance costs. Carbon fiber composites, however, have a density only one-quarter that of steel and half that of aluminum alloy. Airframe components made from them can reduce overall structural weight by 20%-30%. This means spacecraft can carry more scientific research equipment, and aircraft can reduce fuel consumption by over 10%, while also reducing exhaust emissionMore importantly, carbon fiber exhibits exceptional fatigue resistance and resistance to extreme environments. In the vacuum, low temperatures, and intense radiation of space, or under the pressure cycles of frequent takeoffs and landings, it maintains structural stability over time,

resisting the cracking and aging common to metal materials. Furthermore, components such as rocket engine nozzles and satellite solar panel mounts are also made of carbon fiber,

capable of withstanding temperatures reaching thousands of degrees Celsius while avoiding dimensional deformation caused by temperature fluctuations, ensuring the precise execution of space missions.

2.Transportation: Making travel lighter, faster and more environmentally friendly

In the automotive industry, lightweighting is a key path to reducing energy consumption and improving performance. Traditional steel bodies are heavy, increasing engine load. However, carbon fiber bodies, chassis, wheels, and other components can reduce vehicle weight by 15%-25%.

This weight reduction improves acceleration, shortens braking distances, and reduces fuel consumption by 5%-8% per 100 kilometers, making it particularly suitable for new energy vehicles. Lightweighting can directly extend battery life and alleviate "range anxiety."

Furthermore, carbon fiber has excellent energy absorption properties and can absorb impact forces through its own deformation in collisions, providing greater safety for passengers.

In the civilian transportation sector, carbon fiber applications are more practical. For example, high-end bicycle frames made of carbon fiber can weigh less than 1 kilogram, more than half the weight of steel frames, making riding easier and buffering road bumps.

Motorcycle fairings, ski bindings, and fishing rod bodies are also frequently made of carbon fiber, ensuring strength while reducing weight and enhancing the user experience.

3.Medical health: precise and comfortable "life guardian"

Prosthetics and orthotics are the most representative examples. Traditional prosthetics are mostly made of metal or plastic, which are heavy and have poor fit. Long-term wear can easily lead to muscle fatigue.

Carbon fiber prosthetics, on the other hand, weigh only one-third of their metal counterparts and can be customized to the human skeletal shape, resulting in a more precise fit.

They also possess excellent elasticity, mimicking the motion of normal joints during walking, significantly improving mobility. For orthotics for scoliosis patients, carbon fiber is not only lightweight but also provides support while reducing skin pressure and enhancing wearer comfort.

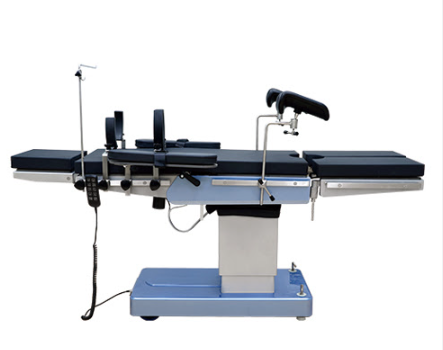

Carbon fiber also plays a crucial role in diagnostic and treatment equipment. For example, the bedplates of imaging equipment such as CT and MRI require high radiation transparency and dimensional stability. Carbon fiber has extremely low X-ray absorption, which does not interfere with imaging.

Furthermore, it resists deformation due to temperature fluctuations or pressure during long-term use, ensuring accurate diagnostic results. Furthermore, the protective components of some radiotherapy equipment are also made of carbon fiber composites,

which not only block radiation but also reduce the overall weight of the equipment and facilitate adjustment of treatment angles.

4.Building and Energy: Reinforcement and Efficient "Invisible Support"

In building reinforcement, the concrete structures of older buildings and bridges often crack due to disrepair. Traditional reinforcement methods involve attaching steel plates, but these are heavy, prone to rust, and increase the load on the structure. Carbon fiber cloth, on the other hand, is highly strong and corrosion-resistant.

When attached to the concrete surface, it forms an integral part, significantly improving the structure's tensile and shear resistance. For the same area, carbon fiber cloth is 5-10 times stronger than steel plate, yet weighs only one-fifth as little.

It also eliminates rust and offers extremely low maintenance costs. For example, in the restoration of historic buildings, reinforcing them with carbon fiber cloth preserves the original appearance while extending their service life.

In the energy sector, wind turbine blades are a key application for carbon fiber. Blade length directly affects power generation efficiency; longer blades capture more wind energy. However, traditional fiberglass blades are heavy and tend to sag and break under their own weight after exceeding a certain length.

Carbon fiber blades are lightweight and rigid, allowing for longer blades (currently exceeding 100 meters). They are also resistant to extreme weather conditions such as strong winds and heavy rain, reducing the risk of blade wear and breakage, and improving the stability and efficiency of wind power generation.

Furthermore, using carbon fiber to manufacture solar photovoltaic brackets reduces their weight, making them easier to install in areas with limited load-bearing capacity, such as rooftops.

5.Sporting Goods: Taking Athletic Performance to the Next Level

For sports enthusiasts, carbon fiber is no longer just a "high-end luxury" item; it's become a "common piece of equipment" that enhances the athletic experience.

In ball sports, golf club shafts, tennis racket frames, and badminton racket frames all utilize carbon fiber extensively. For example, the lightweight and elastic nature of carbon fiber shafts allows golfers to increase club head speed during their swing, allowing the ball to fly farther and more accurately. A tennis racket's carbon fiber frame enhances explosive power while reducing hand vibration and lowering the risk of sports injuries.

In winter sports, carbon fiber is also essential for skis, poles, and curling brushes. Carbon fiber skis offer an excellent balance of rigidity and toughness, allowing them to better conform to the snow and achieve more agile turns. Ski poles made of carbon fiber are half the weight, yet can withstand the impact and pressure of skiing, allowing athletes to more easily maintain balance. Even in diving, carbon fiber wetsuit liners reduce water resistance while maintaining warmth, allowing divers to move more freely.

6.The Future of Carbon Fiber: From "High-End" to "Inclusive"

Today, the applications of carbon fiber are constantly expanding—for example, in drone fuselages (improving flight endurance and payload capacity), laptop casings (reducing weight and enhancing drop resistance), and electrodes for new energy storage devices (improving conductivity). With advances in production technology, the cost of carbon fiber is gradually decreasing, and we may see it in more everyday products in the future.

English

English