What is the forged carbon fiber prepreg ?

- Oct-21-2025

- (128) Views

Forged pattern prepreg (UD+chopped) is an intermediate composite material made by evenly sprinkling chopped carbon fiber on the surface of unidirectional prepreg,

combining it with epoxy resin pre-coated on release film under the action of pressure and temperature, and then cooling, laminating, and winding.

It is a carbon fiber prepreg with an irregular texture effect on the surface, also known as forged carbon fiber prepreg.

Product Features

1. Surface: Unique and beautiful forged grain, no white spots.

2. Lightweight, acid and alkali resistant, and corrosion resistant.

3. Excellent resin flowability.

4. Excellent adhesion and workability.

5. Strong designability.

6. Compatible with a wide range of processes: Product thickness is 0.3mm, making it suitable for a wide range of applications, including autoclave, molding, coiling, and vacuum belt pressing.

7. Excellent mechanical properties.

8. High molding efficiency.

Main molding process

1.The autoclave process is the most common molding method for UD+chopped fiber composites, used in a wide range of applications, including high-end automotive, high-end consumer goods, and sports equipment.

This process involves placing UD+chopped carbon fiber prepreg onto a mold according to the required layup. The prepreg is then sealed in a vacuum bag and placed in a carbon fiber autoclave.

Under vacuum, the autoclave undergoes a series of heating, pressurization, insulation, cooling, and pressure relief procedures. The autoclave's uniform temperature and pressure ensure curing,

resulting in high-quality carbon fiber composite parts with both surface and internal quality.

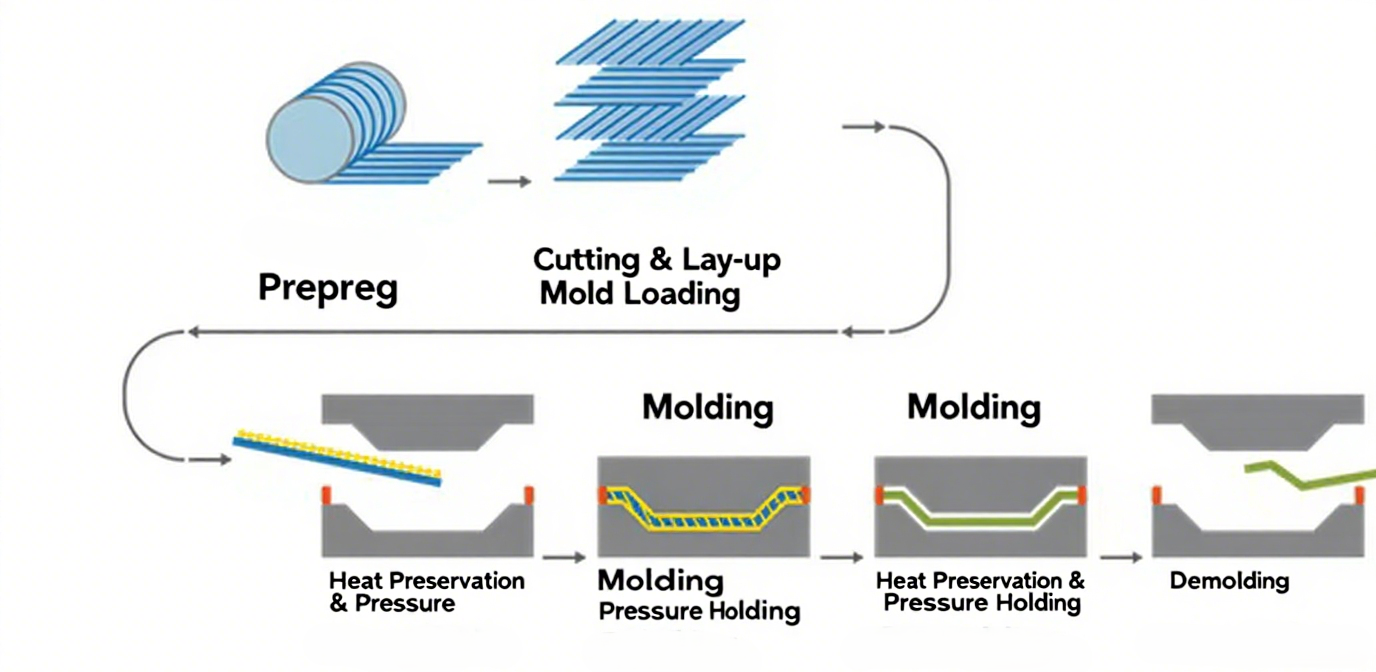

2.Compression molding is a method of adding a certain amount of prepreg into a metal mold and curing it through heating and pressure.

The molded products have high dimensional accuracy and good repeatability; the surface is smooth; and the molding process has relatively high production efficiency, which facilitates specialized and automated production.

In particular, this forged carbon fiber prepreg is fast-curing, with one mold taking 10-15 minutes. The disadvantage is that the mold manufacturing is complex and the investment is large. In addition, due to the limitations of the press,

it is most suitable for the mass production of small and medium-sized composite products, and is not easy to produce large-size products.

3.The tube winding processuses heated rollers on a tube winder to soften the prepreg and melt the resin adhesive. Under a certain tension, the friction between the rollers and the mandrel during the roller rotation is used to continuously roll the prepreg onto the tube core to the desired thickness.

The prepreg is then cooled and shaped by cold rollers before being removed from the winder, wrapped with heat shrink film, and cured in an oven. After the tube has cured, the heat shrink film and core mold are removed to create the composite tube.

English

English