Composite Material Autoclave Molding Process

- Oct-28-2025

- (97) Views

1.Process Principle

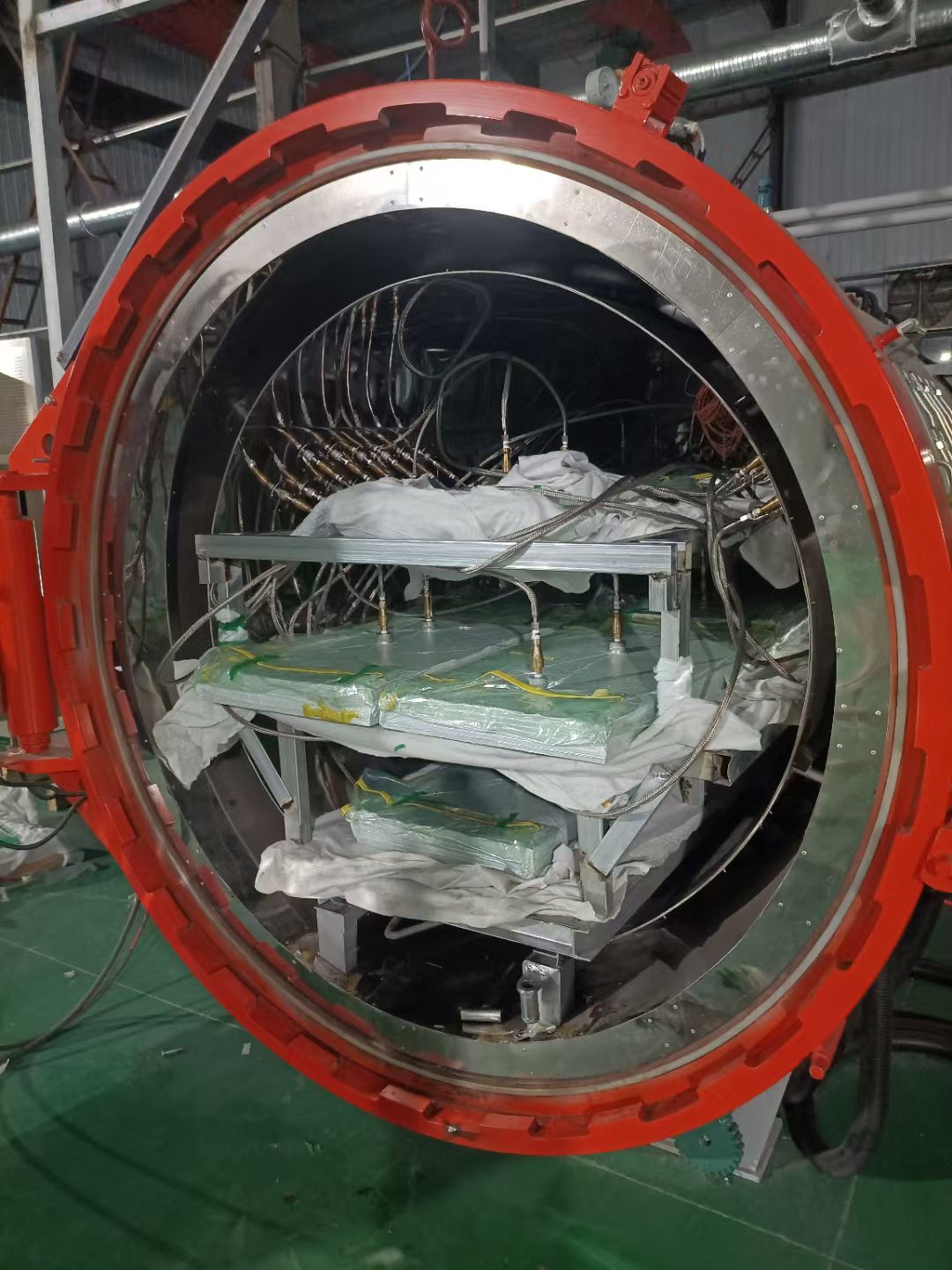

The carbon fiber prepreg is laid on the mold according to the layup requirements, and the blank is sealed in a vacuum bag and placed in a carbon fiber autoclave. Under vacuum conditions, the autoclave undergoes a process of heating, pressurizing, heat preservation, cooling, and pressure relief. The uniform temperature and pressure provided by the autoclave are used to achieve curing, thus forming a carbon fiber composite part with high surface and internal quality, complex shape, and large area.

2.Process Equipment

Autoclave

An autoclave is a process equipment specifically tailored to the specific characteristics of polymer-based composite molding processes. It is the primary method for manufacturing continuous fiber-reinforced thermoset composite parts, and is suitable for forming advanced composite structures, honeycomb sandwich structures, and metal or composite bonded structures. It generally offers advantages such as high temperature and pressure control precision, reliable structure, excellent system stability, low energy consumption, and simple operation and maintenance. It can be modularized and serialized to meet the needs of different applications, processes, and specifications.

Equipment Composition

As a system equipment for curing carbon fiber composite materials, the carbon fiber autoclave can realize the time sequence and real-time online control of process parameters such as temperature, pressure, vacuum, cooling, and circulation. The equipment includes the following components:

(1) Overall structure: It is composed of a tank body, a tank door mechanism, a high-temperature motor, an air duct plate insulation layer, etc. to form a high-pressure and high-temperature tank body.

(2) Safety interlock device: It is composed of a pressure automatic interlock, a manual interlock, and an ultra-high-pressure alarm device.

(3) Quick-opening door device: It is a manual and electric dual-purpose quick-opening door design that can open and close the tank door normally during a power outage;

(4) Sealing device: The tank door adopts a silicone inflatable seal that is resistant to high pressure.

(5) Pressure system: It is composed of a compressor, a gas storage tank, a pressure control valve, a pipeline, a pressure transmitter, and a pressure gauge to form a pressure transmission and control system. The pressure in the tank can reach 1.5-2.5MPa, with an error of no more than 0.05MPa, and is equipped with a safety explosion-proof device.

(6) Heating system: It consists of stainless steel electric heating tubes, high-temperature fans, air duct plates, insulation layers, and temperature control systems. The heating power meets the maximum temperature requirements and heating rate requirements of the cavity.

(7) Temperature circulation system: It consists of a circulating fan, air guide plates, and air guide covers. It accelerates heat flow conduction and circulation to form a uniform temperature field.

(8) Vacuum system: It consists of a vacuum pump, pipelines, vacuum gauges, and vacuum valves. It provides vacuum conditions for the encapsulated composite preforms. Multiple vacuum pipe joints are required to meet the molding process requirements.

(9) Automatic control system: It uses a PLC control system to achieve high-precision control and real-time recording of process parameters such as pressure, temperature, and cooling.

Advantages of autoclave process

(1) Uniform pressure: Gas is used for pressurization, and the pressure is applied to the surface of the product through the vacuum bag. The normal pressure at each point is equal, so that the product is cured and formed at the same pressure at all locations.

(2) Uniform and controllable temperature: The workpiece is heated by a circulating hot air flow in the tank, and the temperature difference at each location is small. At the same time, a cooling system is configured so that the temperature can be strictly controlled within the process setting range.

(3) Wide range of applications: The mold is relatively simple and the efficiency is high. It is suitable for plates and shells with large and complex surfaces, as well as plates, rods, tubes, and blocks with simple shapes. It can also be used for gluing and assembly, and multiple small parts can be cured at the same time.

(4) Stable and reliable molding process: The pressure and temperature are uniform, adjustable and controllable, so that the quality of the molded or transferred products is consistent and reliable; the porosity is low, and the resin content is controllable and uniform; vacuum can be drawn during pressurization to facilitate the discharge of low molecular weight substances.

Disadvantages of the autoclave process

The investment is large and the cost is high. The autoclave connection is complex and expensive. Each use not only consumes water, electricity, gas and other energy, but also requires auxiliary materials such as vacuum bag film, sealing strips, suction adhesives, isolation cloth, etc., which significantly increases production costs.

English

English