Carbon Fiber Plate Production Process

- Oct-30-2025

- (79) Views

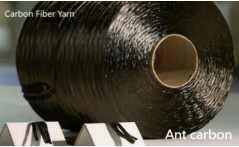

1. Raw Material Preparation

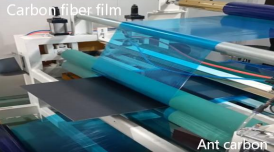

l Carbon fiber yarn (such as T300, T700 and T800) is evenly impregnated in a resin matrix (usually epoxy resin) through a dipping machine.

l The dipping speed and resin content (usually 20%-40%) are controlled, and then dried and shaped to form a roll of "prepreg," the core raw material for producing carbon fiber panels.

2. Cutting and Laying-up

l Prepreg is cut into specific shapes based on the design dimensions.

l Based on the product's load-bearing requirements, prepreg is laid layer by layer at different angles (such as 0°, 45°, and 90°). The number of layers determines the thickness of the panel, while the layup angle determines the panel's strength in different directions

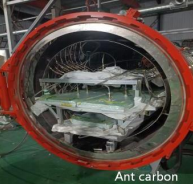

3.Molding and Curing

l The prepreg layers are placed into a mold and pressurized and heated using an autoclave or vacuum bagging process.

l Curing parameters are set (typically 80-180°C, 0.5-2 MPa, and 1-4 hours) to allow the resin to fully flow, crosslink, and cure, firmly bonding with the carbon fibers to form the sheet.

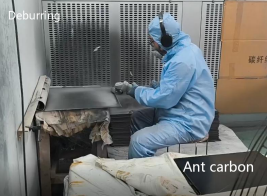

4.Post-processing and Detection

l After curing, the panels are demolded and cut and polished to remove edge burrs and excess material.

l Quality inspections are conducted, including visual inspection (for bubbles and cracks), dimensional measurement, and ultrasonic testing (for internal defects) to ensure compliance with standards.

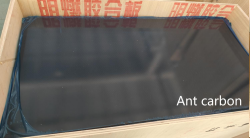

5.Shippment

English

English